Separation of biowaste and biomass

The nationwide introduction of organic waste garbage cans and legal regulations mean that more effective separation technologies are increasingly required for organic waste and biomass. Our SPLITTER enables you to easily process all organic waste in an economical and safe process. This also keeps your costs and efficiency in the green zone.

The all-rounder SPLITTER in use: separation of biowaste and biomass

The actors:

- Biocomposting plants

- Composting plants

- Fermentation plants

- Combination plants

- Fermentation plants

The challenge

- In future, more biowaste will be produced worldwide > existing plants must be expanded accordingly

Practical use of biowaste:

- Pre-separation and pre-conditioning at the start of the process chain. The main objectives are the removal of impurities and homogenization.

- Can also be used as an intermediate step during the maturing process to remove impurities.

- Feed material: Organic waste from box fermentation

- Target material: Marketable compost

The SPLITTER as a solution

- Separation of biogenic material with energy potential

- Contaminants lead to considerable operational disruptions and increased costs with conventional separation technology

- New legal regulations lead to a need for more effective separation technologies

- Insensitive to acids/alkalis/bases/fats

- Used at the beginning of the process chain in dry fermentation to condition the material to e.g. 60-80 mm before fermentation

- Use at the end of the process chain in dry fermentation to safely remove impurities after the fermentation stage/before composting

SPLITTER advantages

- Heavy, wet and small material components quickly find the screen gap due to the density

- Light components float on top and are reliably separated

- Excellent removal of impurities enables the production of a quality product

- The SPLITTER system can be used after fermentation without any problems - even if process fluctuations occur there

- Time-consuming and cost-intensive manual removal of impurities (films) is no longer necessary

- Enables an economical and safe process

- Safe processing of input material containing impurities

- SPLITTER as a pre-separator

Practical example of fermentation and separation of organics/bio-waste and biomass

Use in continuous / discontinuous fermentation

- Conditioning rotted biowaste, digestate and mixtures with green waste or separating light fraction

- Screen cut SPLITTER 120 - 150 mm

- Throughput of 25 to 40 t/h (depending on density and material composition)

Our recommendations:

SPLITTER F2

The chain-mobile SPLITTER F2 is a true all-rounder and separates difficult-to-screen materials into two fractions without clogging or wrapping thanks to its patented screening system.

SPLITTER HOOK

The mobile SPLITTER HOOK achieves the highest possible screening performance on the smallest possible screening surface. Thanks to its robust design, it can effectively process heavy screening materials.

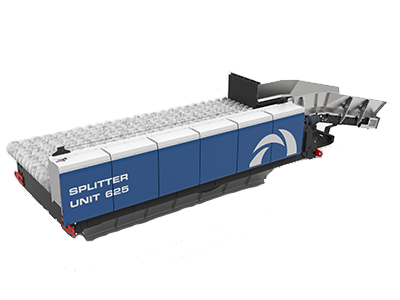

SPLITTER UNIT

With its compact screen deck, the stationary SPLITTER UNIT is particularly suitable as the first step in a process chain for processing solid waste such as commercial and household waste, scrap metal, slag and waste wood.

Your contact person