Plant engineering and processing technology for domestic and commercial waste

For our high-performance, flexible SPLITTER, domestic waste is more raw material than just waste. Its optimum loosening and dosing enables the separation of different materials. Prepared in this way, recyclable materials can be fed back into the recycling process. Our customers benefit from a flexible response to current market requirements and reduced operating costs. This makes our SPLITTER an absolute all-rounder for the separation sector.

The multi-talented SPLITTER separator for use with domestic and commercial waste:

Our customers:

- Disposal companies

- Mechanical treatment plants (MA)

- Mechanical-biological waste treatment plants (MBT)

- Commercial waste treatment plants

- Municipalities

- Disposal companies and manufacturers of refuse-derived fuels (RDF)

- Cement industry

The challenge

- Developments on the market and the legal situation mean that material recycling is becoming increasingly important

- Highly contaminated material tends to wrap and clog the screening system

- Increasing demand for high calorific value fractions (RDF)

- Constant screening performance / quality

Practical examples of domestic and commercial waste

Pre-shredded domestic and commercial waste is separated. The aim is an RDF with a medium calorific value.

Feed material: Pre-shredded domestic and commercial waste

Target material: RDF of medium calorific value with a screening <100 mm grain size

The SPLITTER as a solution

- Separation of high-energy material during pre-screening for the subsequent process

- Problem-free processing of input material containing impurities

- Screening before shredding - reduction of wear and energy costs on the shredder

- High process reliability

- Replacement of inefficient existing technologies

- Good pre-treatment allows valuable materials (e.g. metals) to be recovered and the non-recyclable components of the material can be processed into RDF, for example

The all-rounder SPLITTER in use: separating before or after the shredder

Separation before the shredder

Unshredded domestic and commercial waste is separated as a preliminary stage to the shredder. The aim is pre-separation to reduce wear costs on the shredder (blade life increased from 250 h to 450 h). Feed material: Unshredded household and commercial waste

Target material: Pre-separation of oversized particles (>200 mm goes into the shredder and then into the downstream process), undersized particles (<200 mm goes directly into the downstream process)

- The material flow is separated to protect the downstream units:

- The oversize or good material goes into the shredder

- The undersized particles (e.g. fines / minerals) are separated out

- Low operating costs due to:

- Reduction of wear costs on the shredder

- Reduction of energy costs

Separation after the shredder

- Pre-shredded domestic and commercial waste is broken down and prepared for subsequent processes (optical sorting, FE separation, NF separation, air separation and secondary shredding)

- The SPLITTER at the start of the process enables the separation process to function reliably

- Sieve cut SPLITTER 0-80/100 mm

- Throughput rates of up to 50 t/h

The advantages of the SPLITTER

- Wear-resistant and clogging-free

- Also very suitable for unshredded material

- Optimum loosening and dosing for subsequent processes

- Screen gaps do not clog: consistent screen quality

- Tearing apart of the material flow > low wear on the screen deck

- Dynamic screen gaps > qualitatively and quantitatively consistent screening results

- Oversize grain recirculation to increase throughput while saving wear and energy at the same time

- Self-cleaning effect > low-maintenance system

Treatment plant for substitute fuels - practical example of RDF treatment with SPLITTER technology

The SPLITTER ensures optimum pre-treatment of domestic/commercial waste for future use as substitute fuel, among other things. The optionally pre-shredded or unshredded material is broken down and prepared for subsequent processes such as Fe separation, Ne separation, air separation and post-shredding. Thanks to its unique design, the SPLITTER can combine a number of advantages:

- Self-cleaning effect: turns the SPLITTER into a low-maintenance system

- Tearing apart the material flow: causes extremely low wear on the screen deck

- Low drive power: ensures manageable operating costs for the SPLITTER

- Dynamic screen gaps: enable qualitatively and quantitatively consistent screening results

All subsequent processes benefit from pre-treatment with the SPLITTER, which has a positive effect on system availability and the output of recyclable materials.

The advantages of the SPLITTER are primarily reflected in its alternative application upstream of a shredding stage. Thanks to its specific design and mode of operation, the SPLITTER is also able to process unshredded material effectively. The stress and therefore also the wear on the downstream shredder can be significantly reduced.

MULTISORT - Sorting systems

MULTISORT - Sorting plant for

processing of commercial waste into RDF

MULTISORT - Sorting plant for

processing of commercial waste into RDF

Our recommendations

SPLITTER UNIT

With its compact screen deck, the stationary SPLITTER UNIT is particularly suitable for separating solid waste such as commercial and household waste, scrap metal, slag, waste wood and much more for further processing as the first step in a process chain.

SPLITTER HOOK

The hook-lift mobile SPLITTER HOOK achieves the highest possible screening capacity on the smallest possible screening surface. It is suitable for different types of waste such as domestic and commercial waste, waste wood, organic waste and other types of waste.

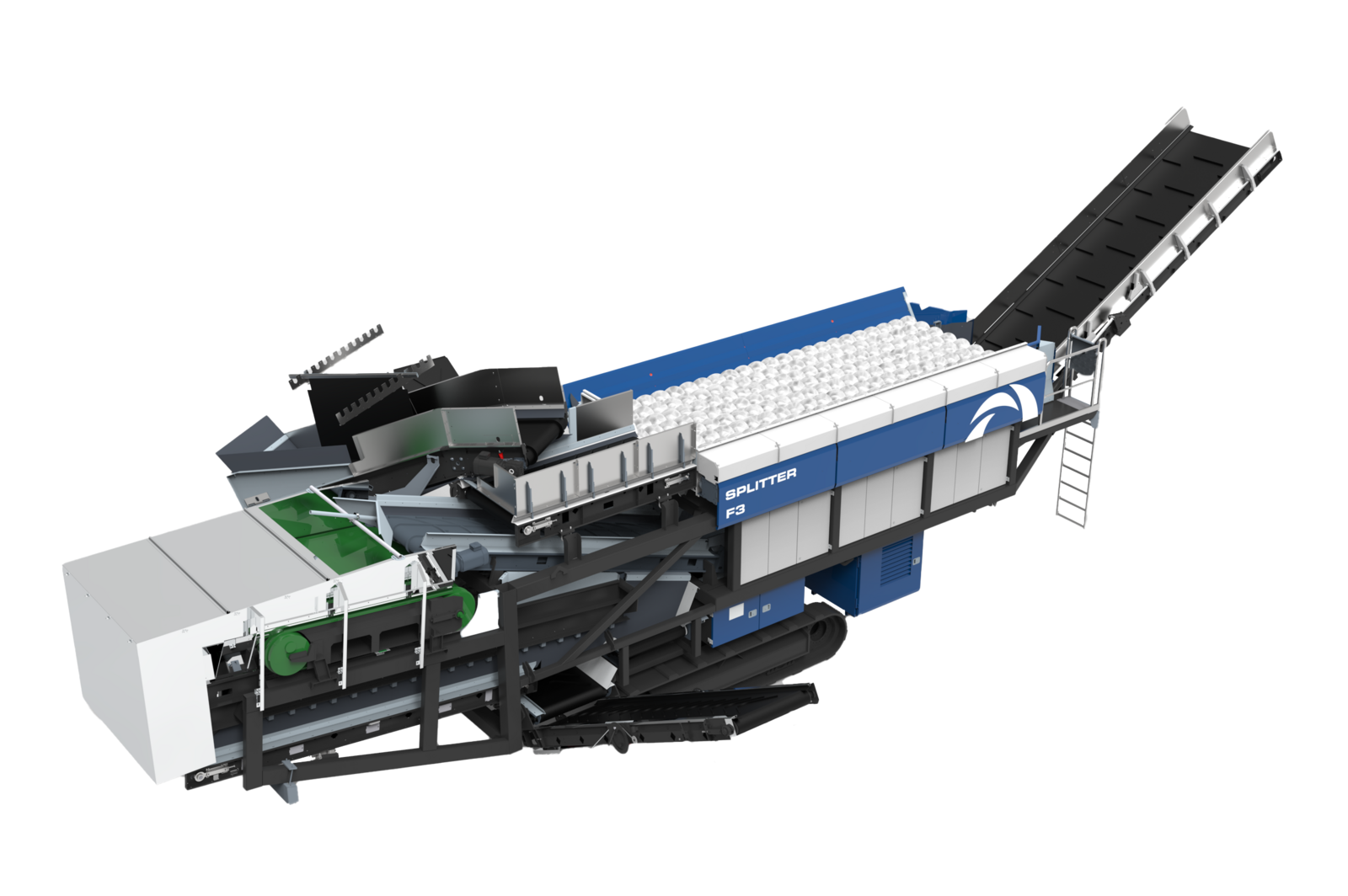

SPLITTER F3

The track-mounted SPLITTER F3 in the F series is the further development of the tried and tested F2 and, with its second screening deck, excels above all in the processing of solid material with a density of up to 0.8 t/m³ (commercial waste, bulky waste).

Your contact person