Separating lightweight packaging is the first step in the sustainable use of resources

The disposal of lightweight packaging and plastics presents us and our environment with a major challenge in the future, as they not only accumulate in large quantities with considerable volumes, but also have the lowest recycling rate of all materials. Although the waste is collected separately in the yellow bag or a garbage can and is also separated from the rest of the waste by the population as far as possible, handling composite materials in the processing and recycling process is often difficult.

New packaging law

The Packaging Act was amended in 2019, meaning that a higher recycling rate must now be achieved in the sorting plants. The packaging must therefore be sorted into the plastic types PET, Tetra, PPK, PP, PVC and HDPE/PE. Metals, such as those used in many cosmetics, are also separated into ferrous and non-ferrous.

Only then can the extracted fractions be passed on in pressed form to a specialist company, which produces recyclate in the form of pellets or flakes and thus achieves a purity of 99%.

Do you have questions about separating lightweight packaging?

SPLITTER technology - the best start to the process chain

According to the Federal Environment Agency, around 18 million tons of plastic waste were produced in Germany in 2016. However, it is not the weight but the large volume of the material that poses a major challenge when it comes to sorting it for recycling. The material passes through various screening and separation steps in the sorting plant, where it is gradually distributed. Most of the volume is therefore clearly produced at the beginning of the process chain in the first screening step. SPLITTER technology is predestined for this due to its high throughput capacity. A SPLITTER screening deck can process a large material flow of LVP per hour with relatively small dimensions.

However, the biggest advantage of the SPLITTER in the process chain is the roller conveyor effect, which is created by the sophisticated arrangement of the spiral shafts in the screen deck. A large proportion of lightweight packaging is delivered to the sorting plant packed in bags. After these have usually been torn open by a bag ripper, they are fed into the separation process. With the help of SPLITTER technology and the associated roller conveyor effect, bags, large films or other interfering long parts can be discharged in the oversize grain in the first screening step, which often also has a positive effect on the accuracy of the screening. Long parts are discharged in the oversize grain in such a way that they can be avoided as far as possible in the undersize grain. Films are also discharged via the roller conveyor effect and do not become entangled in the screen deck. Unlike other screening technologies, this also prevents the formation of tangles.

Patented SPLITTER technology - your benefits:

The patented SPLITTER technology cannot be compared with other screening technologies.

The unique technology offers several advantages when sorting LWP:

- High throughput with a comparably small screen surface area

- Flexible grain size adjustment through screen gap adjustment

- Low wear with low cleaning effort

- Low energy consumption

- No dynamic loads

- Low noise level

Do you have questions about the patented SPLITTER technology?

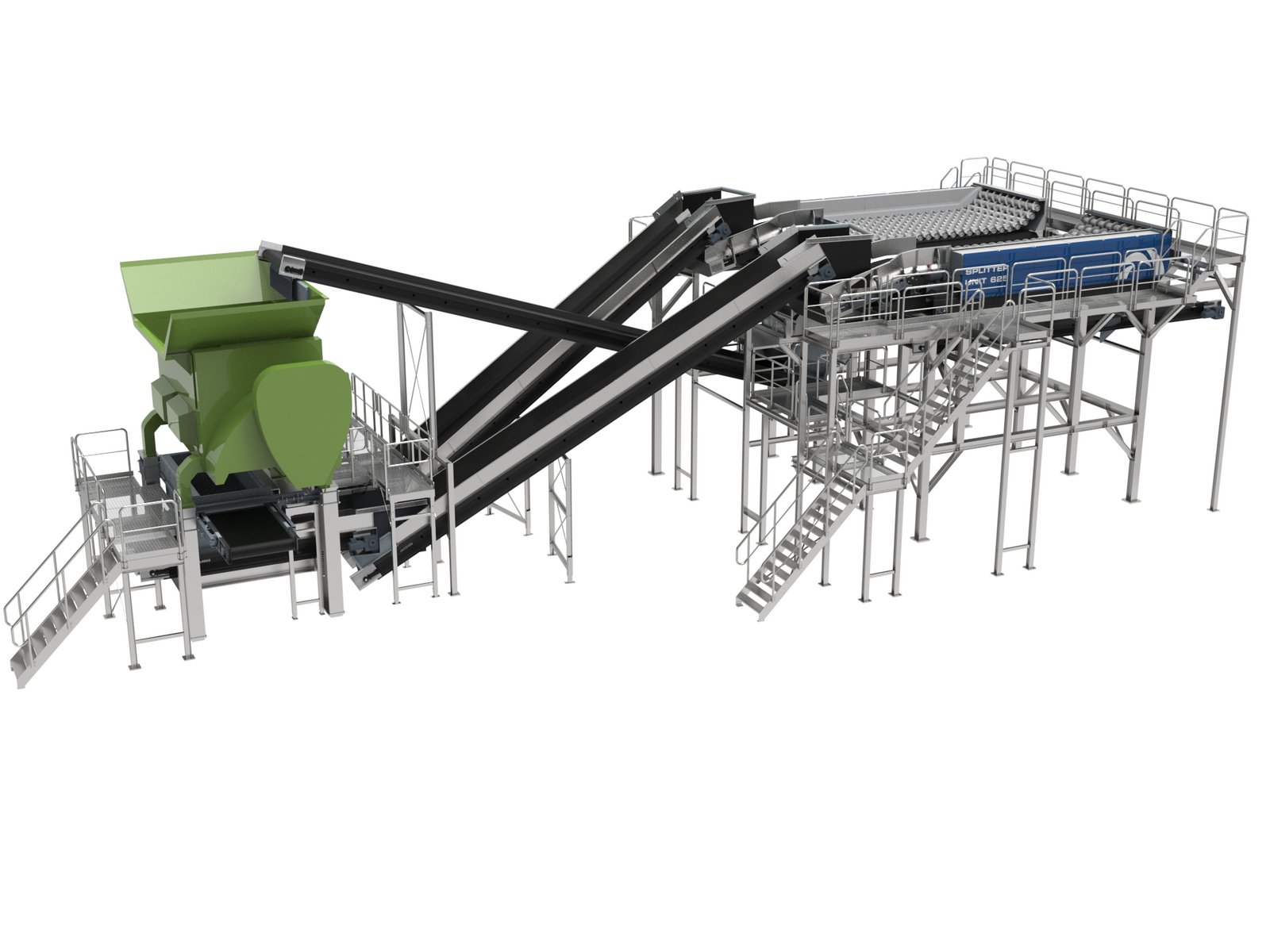

MULTISORT - Stationary sorting system

Reference project Hubert Eing Kunststoffverwertung GmbH

Various separation techniques are used in the plant:

- SPLITTER

- Vibrating screens

- FE separators and NE separators

- NIR sorting technology

- Heavy material separator

- and several film extraction systems

Anlagenbau Günther GmbH is able to plan, design, manufacture and supply complete solutions in the form of stationary systems. For example, the LVP separation plant was built in 2019 at Hubert Eing Kunststoffverwertung GmbH in accordance with the latest standards.

In total, the input material is separated into eight different plastic fractions plus ferrous, non-ferrous and heavy material. The system therefore meets the current recycling rate requirements without the need for manual re-sorting.

The material is fed into the process on a chain belt conveyor as a feeding unit. A shredder serves as a bag opener and distributes the loose material to two material flow lines. A double SPLITTER screen deck is used to process the two material streams and thus ensure a high throughput. It reliably removes long parts and oversized materials such as film and bags from the material flow. The fine fraction first passes through a vibratory screen, a counter-rotating non-ferrous and ferrous de-airing system, an air classifier and several near-infrared systems (NIR separators), which sort the various plastics into PET, Tetra, PPK, PP, PVC and HDPE/PE based on their physical properties.

The output streams are pressed fully automatically from the light material bunkers. The resulting sorting fractions are transported via buffer storage in batch operation on a long conveyor belt to the press and pressed for further processing. The residual plastics that cannot be sorted for recycling pass through a heavy material separator before being processed into substitute fuel. The exhaust air from all sifter systems and transfer points is fed into a dedusting system and cleaned in accordance with the applicable legal requirements.

The scope of delivery for the project also included the electrical installation, circuit diagrams and system programming. Three control stations are available to control the system. Approx. 50 conveyor belts, approx. 110 tons of steel construction and approx. 500 m of walkways were installed on a total area of 2400 m². Thanks to the after-sales service, the customer always has a contact person and a reliable supply of spare parts.

Our product recommendations for separating LWP:

SPLITTER DUO

The SPLITTER DUO comprises two SPLITTER spiral shaft screen decks and is therefore particularly suitable for processing large, voluminous material flows. This makes it ideal for use at the beginning of the process chain as a pre-separator.

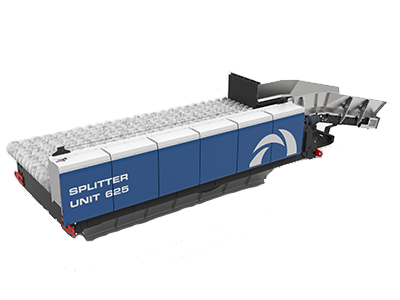

SPLITTER UNIT

With its compact screen deck, the stationary SPLITTER UNIT is particularly suitable as the first step in a process chain for processing solid waste such as lightweight packaging, commercial and household waste, scrap metal, slag, waste wood and much more.

SPLITTER F2

The SPLITTER F2 is a true omnivore and separates materials that are difficult to screen (e.g. lightweight packaging, domestic and commercial waste, bulky waste, landfill deconstruction) into two fractions without clogging or wrapping, thanks to its patented screening system.

Your contact person