Plant engineering and processing technology for mixed construction waste

The SPLITTER effortlessly processes coarsely pre-sorted mixed construction waste, bulky waste and commercial waste and separates them into virtually unmixed stone and fuel fractions that can be easily sent to landfill. It achieves a throughput of up to 50 t/h. With this speed, flexibility and efficiency, you can also rely on the SPLITTER economically.

The actors

- Demolition company

- Construction companies

- Municipalities

- Container companies

The challenge

- The slightest impurities turn construction waste into mixed construction waste and thus increase disposal capacities at landfills

- Demanding material that is difficult to screen

- Reuse of ingredients to conserve resources

Construction waste sorting plant in practice

The aim is to pre-separate coarsely pre-sorted mixed construction waste into an almost unmixed stone and fuel fraction, and to remove the minerals.

Feed material: Mixed construction waste pre-sorted by excavator

Target material: Pre-separation of oversized particles (stones and fuel fraction) / undersized particles (removal of minerals) with a grain size of 0 - 80 / 120 mm

The SPLITTER as a solution

- Separation of a fraction with a high calorific value (e.g. packaging), which can thus be removed from the process chain and passed on to other processors

- Separation of a cubic fraction that is suitable for landfills or as a secondary building material

- Clog-free separation of the undersize fraction, in order to use it - depending on its composition - as backfill material in landfills, for example

The SPLITTER advantages

- Effective separation of the individual components from construction waste and mixed construction waste

- Enables the processing of material that is difficult to screen

- Fast and cost-saving separation

Practical example of processing stone/burning fraction and RC material

Processing of stone and fuel fraction

- Processing and conditioning coarsely preconditioned mixed construction waste to produce medium-calorific substitute fuel or a mineral residual fraction for subsequent further processing

- Throughput of up to 50 t/h

- Several SPLITTER units connected in series with different screen sections from 10 to 400 mm

Preparation of RC material

- Processing of mixed construction waste, bulky and commercial waste into secondary raw materials and fuel

- Throughput and screen cut according to customer requirements

Depending on customer requirements, the processing depth can vary from coarse pre-separation to fine processing thanks to the multi-stage use of the SPLITTER.

The individual integration of individual processing steps in the different SPLITTER fractions (e.g. FE removal, air separation) enables the processing of e.g. RC material, fuels, FE fractions and minerals into high-quality end products.

The SPLITTER advantages

- Separation of an almost unmixed stone fraction and firing fraction

- Flat installation situation

- High process reliability due to robust design

- Insensitive to impurities

- Can be retrofitted in almost all existing plants thanks to its compact size

- Optimum processing of the stone fraction for feeding to a crusher > Recycling material (RC material) as secondary raw material

- Separation of a stone-free fraction > Fuel

Our recommendations

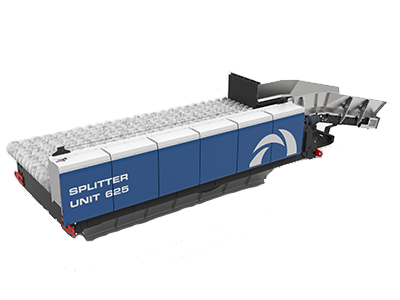

SPLITTER UNIT

With its compact screen deck, the stationary SPLITTER UNIT is particularly suitable as the first step in a process chain for processing solid waste such as commercial and household waste, scrap metal, slag and waste wood.

SPLITTER HOOK

The hook-lift mobile SPLITTER HOOK achieves the highest possible screening capacity on the smallest possible screening surface. Thanks to its robust design, it can effectively process heavy screening material.

TAKER HOOK

The TAKER receiving feeder impresses with its large capacity and high flexibility. It conveys loose material smoothly to the downstream units - the optimum solution with high efficiency.

Your contact person