Plant engineering and processing technology for scrap metal

Metals are now almost 100% recycled. The SPLITTER makes a significant contribution to the recycling of scrap metal. As a pre-separator, it removes material adhesions and pollutants and thus produces high-quality scrap for the processing industry.

The actors

- Raw material dealers (scrap metal)

- Specialist disposal companies (metals)

The challenge

- Removal of mineral components (sand, etc.), e.g. from loading scrap

- Removal of adhesions

- Increasing the added value in the material flow

Practical use of loading scrap

The quantities of loading scrap produced are often heavily interspersed with minerals. With SPLITTER technology, the minerals can be easily screened out of this extremely contaminated material mix. This results in a clean scrap fraction in the oversize grain and the undersize grain can be further processed as required.

Feed material: loading scrap, shear scrap

Target material: clean scrap fraction without adhesions, e.g. larger than 60 mm, which can be fed back into the recycling cycle

The SPLITTER as a solution

- Separation of a clean oversize fraction to secure raw materials for metal extraction

- Separation according to material size

- Clog-free separation of the undersize fraction

- If required, an FE separator can be used to additionally remove FE from the undersize or oversize particles

The advantages of the SPLITTER

- Effective separation of individual components from any metal-material mix

- Enables the processing of difficult-to-screen material

- Fast and cost-saving separation

Our recommendation

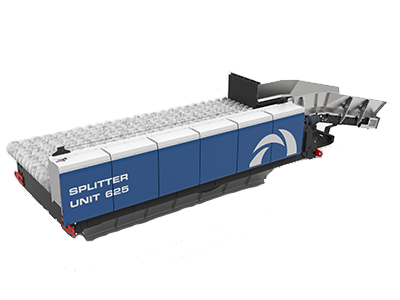

SPLITTER UNIT

With its compact screen deck, the stationary SPLITTER UNIT is particularly suitable as the first step in a process chain for processing solid waste such as commercial and household waste, scrap metal, slag, waste wood and much more.

SPLITTER HOOK

The mobile SPLITTER HOOK achieves the highest possible screening performance on the smallest possible screening surface. Thanks to its robust design, it can effectively process heavy screening material such as mixed construction waste, scrap metal and slag.

RETURNER

The RETURNER return unit is the ideal complement to the SPLITTER HOOK. The RETURNER can be used, for example, to transport the oversize grain from the reversible discharge conveyor of the SPLITTER HOOK directly into a container.

Your contact person