Processing of sewer sand, caisson material and road sweepings

There are always deposits of sand and various organic substances in our sewer system. Due to our own or the economical behavior of today's technology, less and less water is being used, which encourages deposits in the sewer system. Sewer systems are regularly cleaned and flushed to prevent the build-up that can cause major problems in the long term. The material - a mixture of wastewater, sand and organic matter - is pumped out using vacuum trucks.

The GÜNTHER machines SPLITTER CUBE (stationary) and MULTIWASH HOOK (hook-lift mobile) were developed to prepare this material, as well as road sweepings and cesspit material, for recycling and to feed it into the circular economy as ecologically and economically as possible. Both screens are suitable for feeding dry and wet materials. The stationary SPLITTER CUBE contains a feed chute including a SPLITTER screen. The screened material is then washed in subsequent units. The mobile MULTIWASH HOOK variant combines feeding, screening and washing in one unit.

Do you have questions about processing sewer sand or road sweepings?

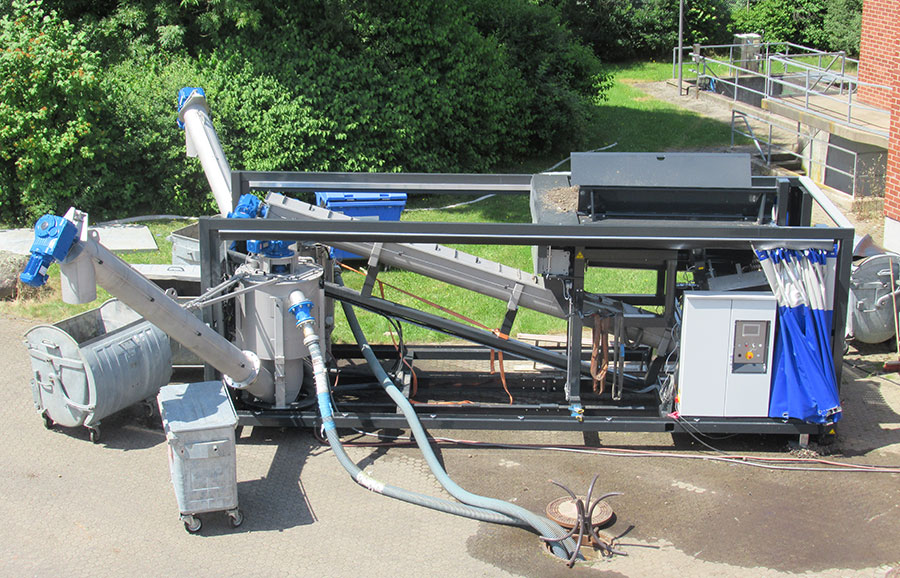

MULTIWASH HOOK - flexible thanks to hook lift mobility

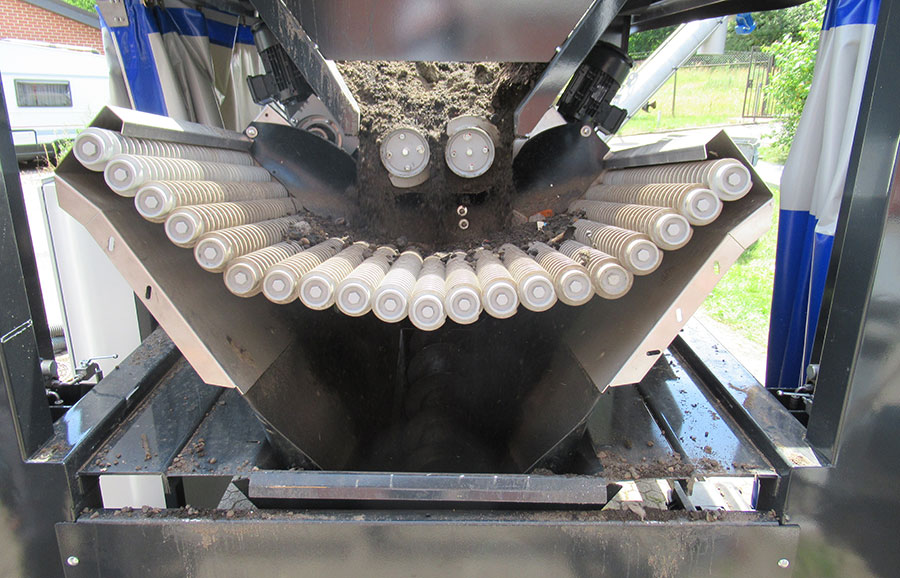

The material is fed into the machine via a hopper. From this, it is conveyed onto the SPLITTER TWIN WAVE screen deck by a screw conveyor. Impurities >15 mm are separated out in the oversize grain. The organics are removed from the undersized material in the sand washer so that the final product is sand that contains only 3-5 % organics and is therefore processed as efficiently and recyclably as possible.

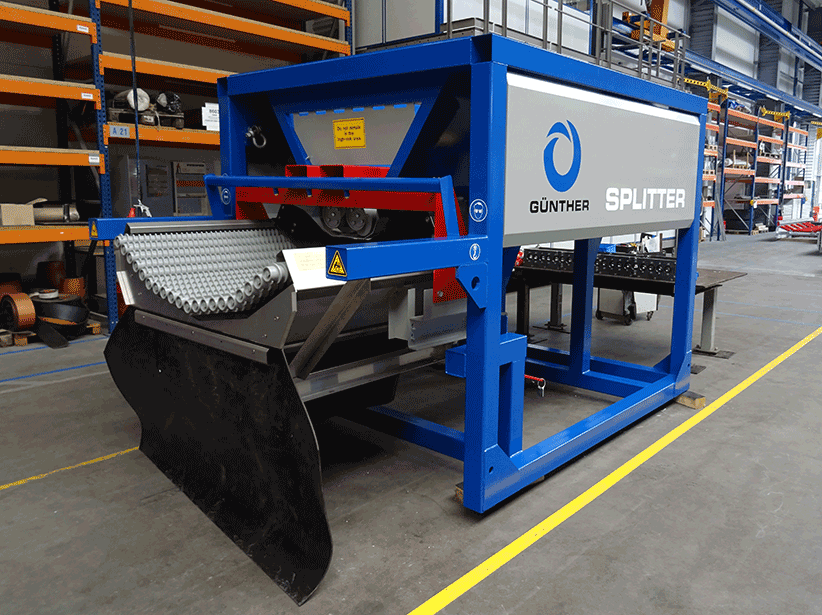

SPLITTER CUBE

The stationary SPLITTER CUBE consists of a vibrating or flume feeder and a SPLITTER screen deck. The machine is completely pre-assembled and ready for operation, requires little space and can be optimally combined with various upstream or downstream machines. It impresses with a high throughput of up to 15 m³/h of solids.

MULTIWASH HOOK vs. SPLITTER CUBE

Advantages of the MULTIWASH HOOK:

- No building permit due to hook lift mobility

- Saves CO2 through on-site use

- Can be transported and moved as required thanks to compact design

- Integrated feed hopper, pre-screening and washing system in one

Advantages of the SPLITTER CUBE:

- Low space requirement and low construction costs

- High throughput of up to 15 m³/h solids

- Flexible integration options in the process chain

- Various project-related options possible (e.g. sand washing system or additional conveyor technology)

Further advantages of our machines for the waste water and sewer sand sector:

- Flexible material intake, dry or wet

- Unique, self-cleaning screen system

- No plait formation with winding materials

- Low cleaning and maintenance requirements

- External dimensions of the machine = internal container dimensions = low transportation costs

- Compact, easy to transport by truck

- Completely pre-assembled and ready to use

- Simple assembly and handling

- Very stable design

Your contact person