The separation multi-talent SPLITTER in use: Processing slag

Ash and slag from incineration plants and substitute fuel power plants are not only waste, but often also have great raw material potential. When processing the bottom ash, the SPLITTER helps to separate "clean" ash, i.e. without unburned material residues, in addition to iron and non-ferrous metals. This can then be used in road construction, for example.

Task definition

- At the beginning of the process chain

- Used for the separation of coarse impurities for processing with conventional machine technology

- At the end of the process chain

- Separation of the non-ferrous and aluminum components and the unburned material from the material flow for subsequent further processing

- The contaminant-free fines can be reused in road construction, for example

Advantages of the SPLITTER

- Robust and insensitive to contaminants

- Reduction of the landfill volume

- Production of landfillable materials

- Powerful and safe technology

- Insensitive to temperature and moisture

- "Fresh slag" can be processed

Practical use of MVA slag

Pre-separation of fresh or deposited waste incineration slag. In the first screening process, the impurities must be removed from the material flow in order to subsequently feed these material flows back into the downstream systems for a smooth process.

Feed material: Slag with impurities

Target material: Impurities 70 mm to x / undersize particles with a grain size of 0 to 70 mm

Our recommendations:

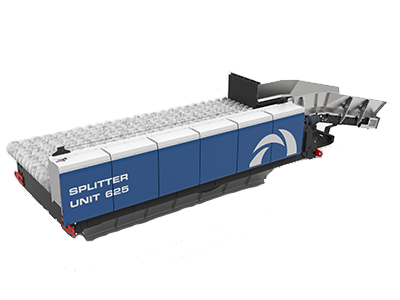

SPLITTER UNIT

With its compact screen deck, the stationary SPLITTER UNIT is particularly suitable as the first step in a process chain for processing solid waste such as commercial and household waste, scrap metal, slag, waste wood and much more.

SPLITTER HOOK

The mobile SPLITTER HOOK achieves the highest possible screening performance on the smallest possible screening surface. Thanks to its robust design, it can effectively process heavy screening material such as mixed construction waste, scrap metal and slag.

RETURNER

The RETURNER return unit is the ideal complement to the SPLITTER HOOK. The RETURNER can be used, for example, to convey the oversize grain from the reversible discharge conveyor of the SPLITTER HOOK directly into a container.

Your contact person