Our MULTISTAR star screen - The star screen technology of our star screening machines stands for economy and efficiency

Screening is an elementary treatment step in the processing of waste, recyclable materials and biomass. Star screen technology is increasingly being used for this purpose. And in most cases it is a MULTISTAR star screen. It's easy to explain why: one machine and one operation are enough to divide the screened material into 2 or 3 fractions in exact screening. The throughput rate and separation efficiency are maintained even with increasing material moisture - thanks to the patented CLEANSTAR cleaning system.

If you want to adjust the grain size, all you have to do is press a button - the machine does the rest. Thanks to the highly efficient drive, screening is quiet, safe and economical. You will find the right equipment for almost every application and plant size. The screening plant becomes multifunctional through extensions such as magnetic separation, air separation or roller separation - everything is possible.

The MULTISTAR technology

is distributed exclusively by our partner

KOMPTECH.

Get information now

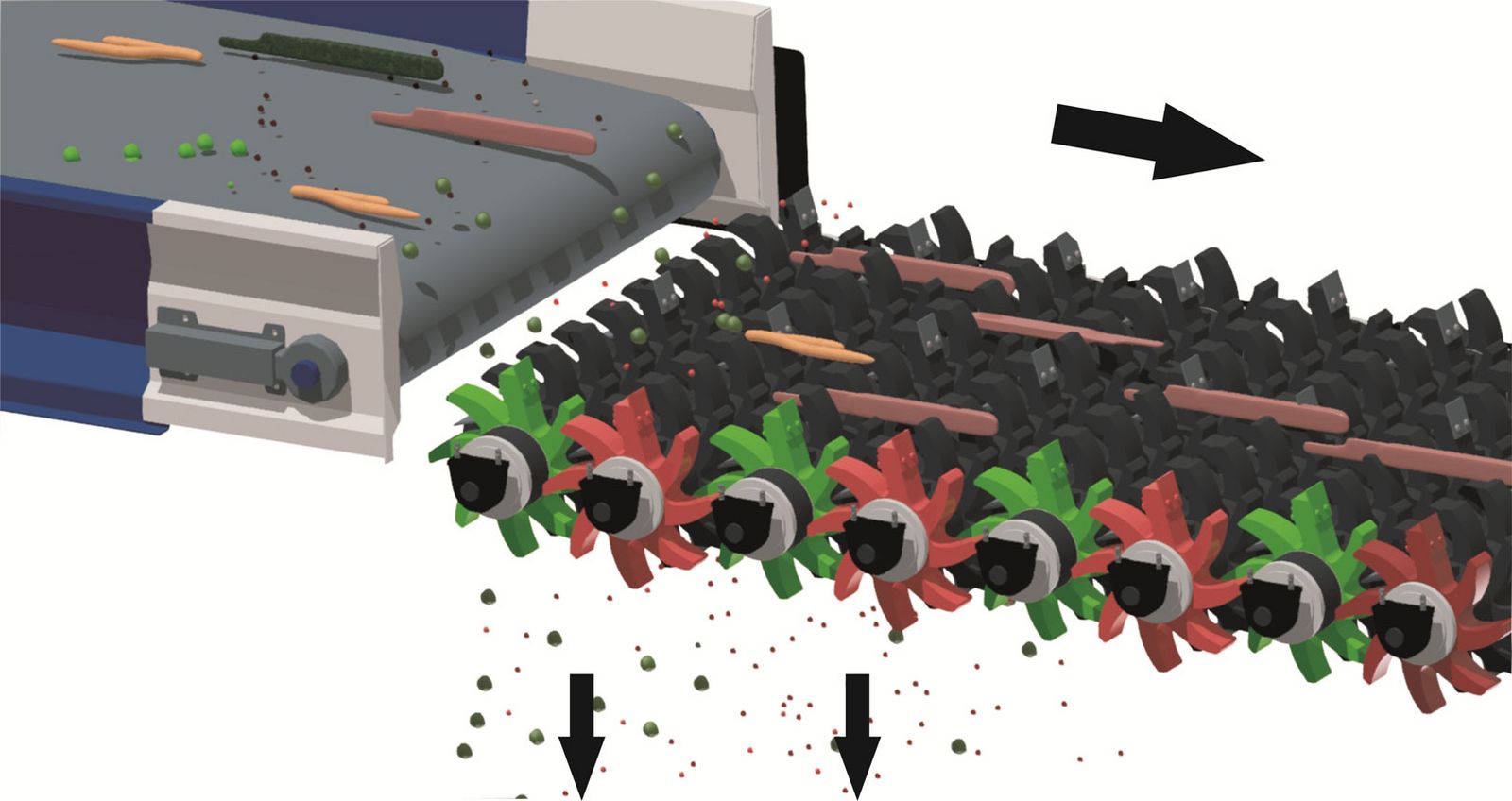

The functional principle of our star screen technology: first coarse - then fine

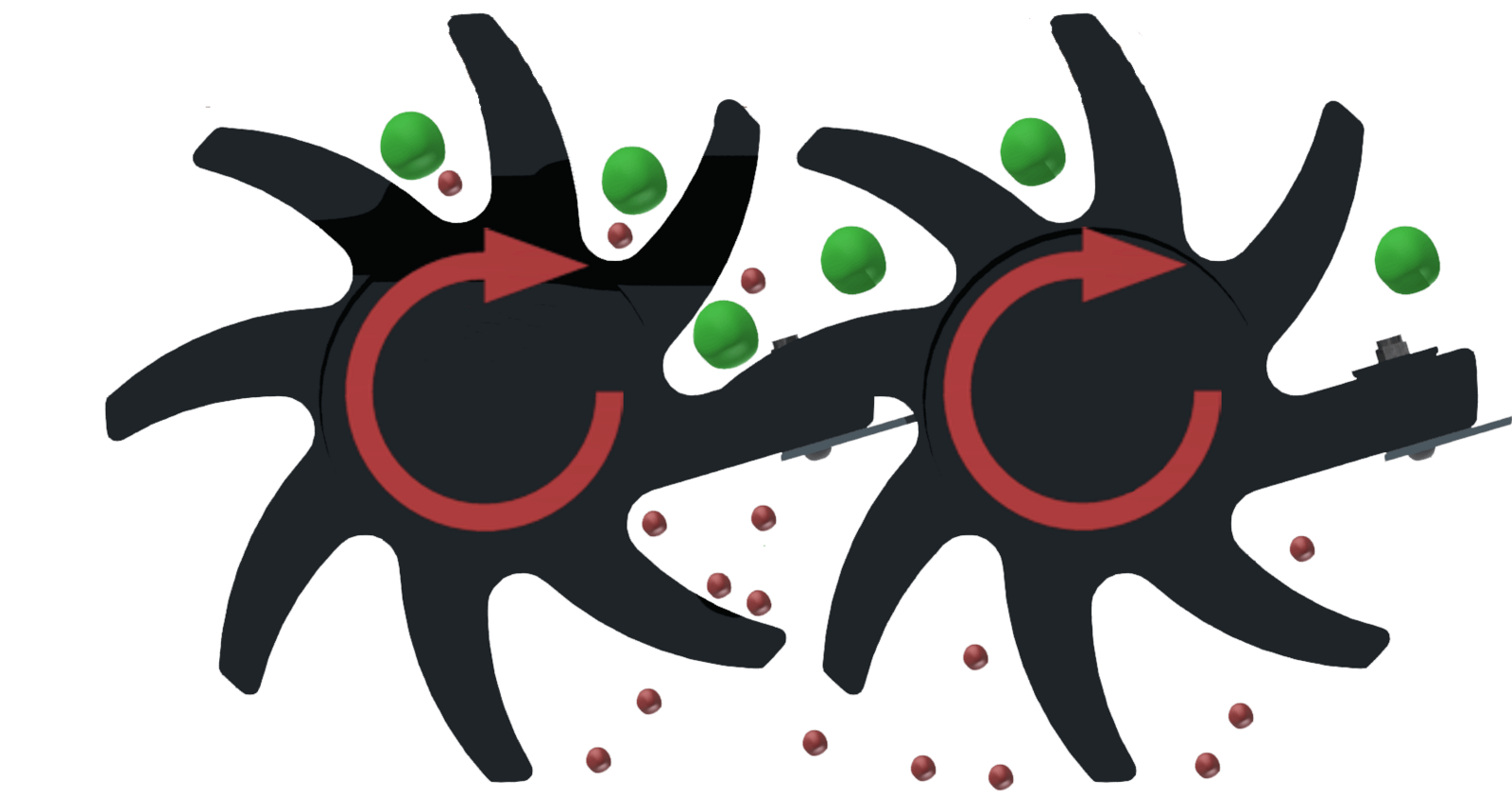

The inner workings of the star screen machines consist of one or two screen decks, depending on the design. The rotating shafts of the coarse screen deck convey the material in a horizontal direction. Anything that cannot pass the defined distance between the stars is separated as coarse grain and transported further. The screened material passes through to the fine screen deck equipped with smaller stars and is split into a fine and medium fraction according to the same principle. The principle of coarse screening before fine screening provides a high screening quality, enables a high screening capacity with a shorter screen length and protects the fine screen from more solid impurities.

The grain size is changed by adjusting the speed of rotation of the star shafts. The grain size can be changed within seconds from the control panel via frequency converters within the bandwidth specified by the star geometry. A central control unit monitors all functions and provides information on the current operating status.

How the MULTISTAR star screen with CLEANSTAR cleaning system works

The function is demonstrated in an impressive way using various simulated materials. We would be happy to advise you on the applications in your specific environment and according to your needs!

Visit the YouTube channel of our sales partner Komptech for further application and machine-specific MULTISTAR examples and information.

Arrange a consultation right away:

Advantages of MULTISTAR star screen technology

- Separation into 2 or 3 fractions with one machine and in one operation

- High throughput rate with precise separation precision thanks to the CLEANSTAR system

- Great flexibility thanks to grain size changes in seconds

- Convenient operation and easy maintenance thanks to intelligent machine design

- Multifunctional thanks to numerous options such as wind sifting and FE separation

- Extremely economical; high throughput with low energy and wear costs

- Mobile and flexible application options

- Proven 1000 times over

Our MULTISTAR - products

MULTISTAR ONE

The new MULTISTAR ONE processes waste wood and biomass with maximum efficiency. An upstream shredder, the Crambo from Komptech, feeds the ONE with the shredded material.

Overview

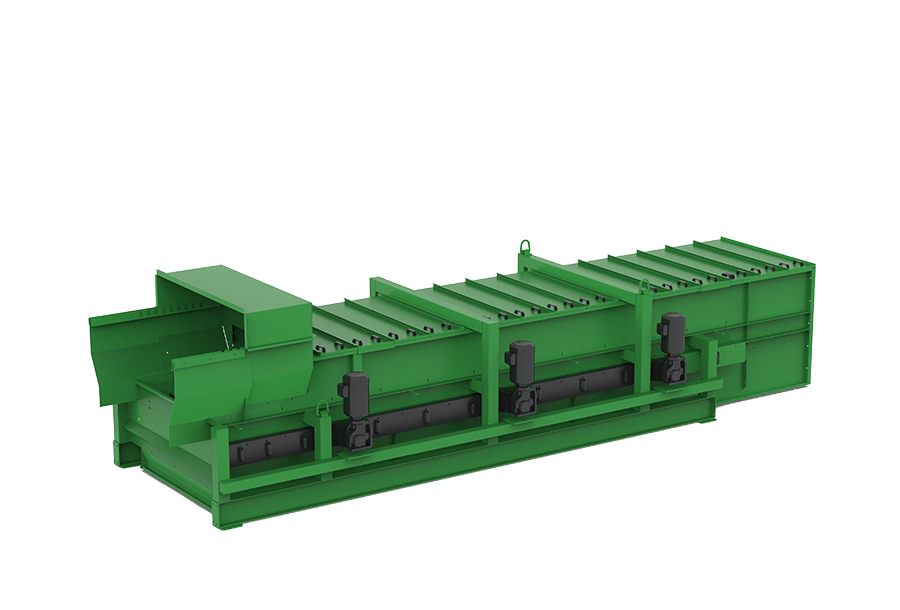

MULTISTAR S3

The hook-lift mobile Multistar S3 is Komptech's entry into professional star screen technology. Designed precisely for the requirements of the lower and medium performance class.

MULTISTAR XL3

One feature of the XL3 is the extra-long coarse screen deck: Wherever this first screening step is the bottleneck - for example with fresh biomass - the screening capacity can be significantly increased.

MULTISTAR XXL2

The MULTISTAR XXL2 is designed as a pure 2-fraction star screen machine with a replaceable screen cassette and therefore offers maximum capacities of up to 500 m³/h in this area with quick-change applications.

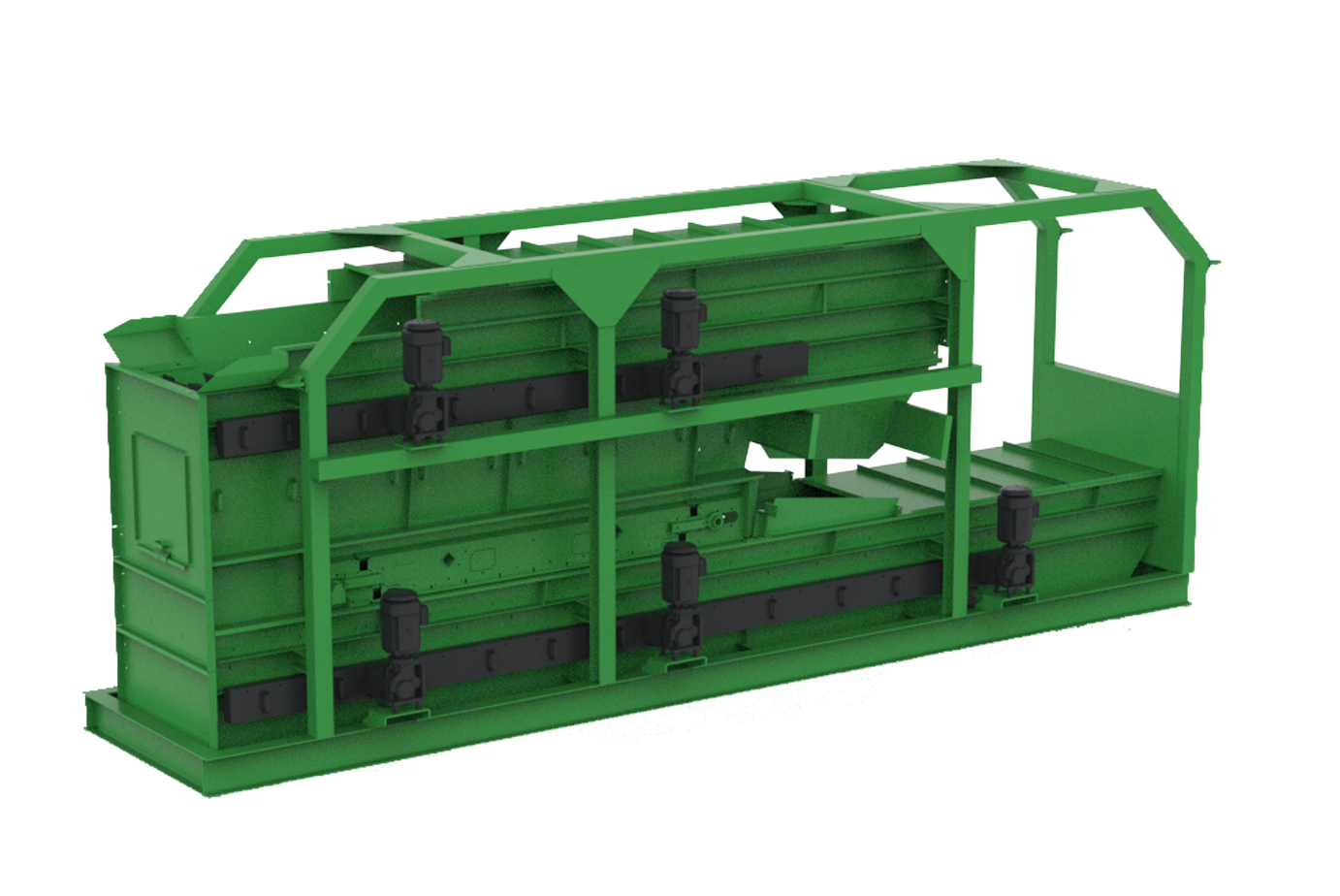

MULTISTAR 2-SE

The MULTISTAR 2-SE star screen is an easy-to-integrate solution thanks to its compact design. A modular system with options such as substructure, feed dosing hopper with feed and discharge belts.

MULTISTAR 3-SE

The MULTISTAR star screens are not only among the most efficient screening machines, they are also hard to beat in terms of cost-effectiveness. Compost, bark and biomass are separated efficiently and with maximum reliability.

MULTISTAR 2-SE Wet sieve

With the patented Cleanstar® system, the screens have an integrated cleaning system that works without contact and therefore protects against wear. The sieve stars are cleaned without additional brushes or washing water.

Areas of application

Biomass (green cuttings, rootstocks, forest residues, fresh compost)

Compost (green compost, organic compost, sewage sludge compost)

Wood (treated / untreated waste wood, wood chips, bark)

Waste (commercial waste, household waste, residual waste)

Your contact person