Advantages of the MULTISTAR S3 at a glance

Arrange a consultation right away:

Perfect for getting started

Low investment costs are not at odds with performance and ease of use. A hopper with a volume of up to 3.5 m³ guarantees continuous operation, while a coarse screen with 2.1 m² and a fine screen with 3.9 m² screening surface provide efficient separation work. The discharge height of the discharge conveyors creates the necessary buffer for optimized wheel loader operation.

A different kind of cladding

Sheet metal cladding with large maintenance doors is located in the drive area. In the other areas, a weight-saving cladding made of robust truck tarpaulin provides both protection against dirt and an unmistakable machine design. Once the tarpaulin has been rolled up, there is free access to all other components.

Always clean thanks to CLEANSTAR

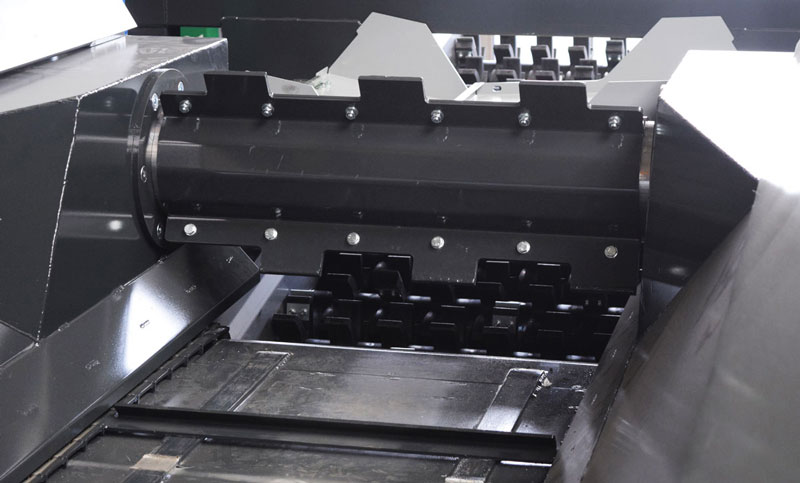

The patented CLEANSTAR system ensures the simplest and most effective self-cleaning of the screen decks. Each star has tried-and-tested, wear-resistant cleaning elements that clear the screen gap to the surrounding stars with every rotation. This means safe use in all seasons.

MULTISTAR S3 star screen - perfect for getting started

The Multistar S3 marks Komptech's entry into professional star screen technology. Designed precisely for the requirements of the lower and medium performance class, the S3 scores with both low investment costs and performance features that were previously reserved for high-performance machines in the L and XL class.

The MULTISTAR technology

is distributed exclusively by our partner

KOMPTECH.

Get information now

Wide range of applications for the MULTISTAR S3

The design on a hook lift module creates compact dimensions and still offers the necessary mobility for service providers or inter-company use. Just as in the performance classes above, the range of applications extends from compost, green waste, bark and wood chips to pre-shredded waste wood.

The choice of screen grain sizes in particular makes this machine universally applicable. And in terms of options, almost all features of the upper class are available: Wind sifting on the center grain, screen deck variations, switching from 3 to 2 fractions, bunker increases and much more.

Highlights of the MULTISTAR S3

- Hook-lift mobile 3-fraction star screen with compact dimensions

- High throughput capacity of up to 100 m³/h

- Large hopper with a volume of up to 3.5 m³ and low loading height

- Optimum accessibility thanks to maintenance doors and easy-to-operate tarpaulin cover

- Multifunctional thanks to numerous options

- Hybrid technology: power for the drives from the mains or from the diesel generator

You want to test your material:

Technical data

| Drive | Engine: Diesel generator 38 kVA (50 kVA option) |

| Material feed | Bunker volume (m³): 2.5 (3.5 option) Filling length (mm): 3100 Feed height (mm): 2500 / 3000 |

| Sieve unit/sieve section | Coarse screen L x W (mm) / area (m²): 2400 x 900 / 2.1 Fine screen L x W (mm) / area (m²): 4250 x 900 / 3.9 Coarse grain (mm): > 60 ... 90 Medium grain (mm): 10 ... 25 / 60 ... 90 Fine grain (mm): 0 / 10 ... 25 |

| Material discharge | Max. Discharge height coarse grain (mm): 2300 Max. Discharge height medium grain (mm): 2900 Max. Discharge height fine grain (mm): 2300 |

| Areas of application | Pre-shredded waste wood of all classes, burl wood, green shredded material, bark, wood chips, biomass, compost |

| Troughput | up to 100 m³/h (depending on material) |

| Weight | ~ 10.0 t (depending on equipment) |

| Dimensions | Transport dimensions L x W x H (mm): 8200 x 2450 x 2560 Working dimensions L x W x H (mm): 11066 x 5542 x 3000 |

| Options | Screen deck variants, diesel generator, magnetic drum, wind sifter, radio remote control, switching from 3 to 2 fractions, transfer wall for bunker, hydraulic support legs, direct connection and much more. |

You can find more mobile machines here:

Your contact person