What plants does GÜNTHER build?

Günther's plant engineering is specially adapted to the requirements of the recycling industry. Our core competence is in the field of processing and sorting plants for various waste and recyclable materials. For decades, we have been developing intelligent technologies in the field of mechanical treatment and holistic concepts for waste management.

Which advantages do you have with a recycling system from Anlagenbau GÜNTHER?

- Use of high-quality components from our own company

- Partner and manufacturer-independent use of industry-standard units

- Turnkey solutions for many materials

- Intensive advice from experts and industry insiders

- Made in Germany

- High vertical range of manufacture in-house at GÜNTHER

- Reduced interface clarification

- A dedicated project manager as contact person for all matters

- Technically trained specialists

- The GÜNTHER mounting teams consist to a large extent of GÜNTHER's own employees, who control the process and tackle the work themselves.

- The complete electrical engineering is optionally supplied by us

- High flexibility and adaptability to customer requirements

- High quality standards

- Highly reputable manufacturers for purchased parts

- Reuse of existing units possible

- Comprehensive after-sales service

MULTISORT - Sorting systems

MULTISORT - Sorting plant for

processing of commercial waste

to RDF

MULTISORT - Sorting system for

processing of lightweight packaging

MULTISORT - Sorting plant for

processing of waste wood

ANLAGENBAU GÜNTHER - Plant engineering "Made in Germany"

At our Wartenberg site in Germany, we have in-house specialists in all departments, from process technology, engineering and electrical engineering to our mechatronics engineers, who provide comprehensive after-sales support. Our employees include experts who have been with us or in the industry for many years, as well as young employees who have the necessary vision. Our high training and hiring rate also enables us to secure our specialists for the long term. We therefore cover the entire value chain in-house. From sales and conceptual design to construction, manufacture, assembly, training, commissioning, service and spare parts supply. Every day, over 140 employees at ANLAGENBAU GÜNTHER work closely with customers to develop cost-effective solutions for recycling systems.

Recycling technology with quality

We ourselves manufacture star screens (in cooperation with Komptech), SPLITTER, intake feeders and conveyor technology, among other things. Of course, we are happy to use these core competences at the appropriate points in the system - because we are convinced of the quality and functionality of our technology. In addition to our own portfolio, we also use other manufacturer-independent components. The units can be planned and integrated according to customer requirements.

Our components:

- Star screens

- SPLITTER

- Receiving feeders

- Conveyor technology

- Electrical engineering

- Steel construction and inspections

Other components:

- Shredder

- FE separator

- Non-ferrous separator

- Air classifier

- NIR separator

- Various screening systems

- Sorting cabins

- Extraction systems

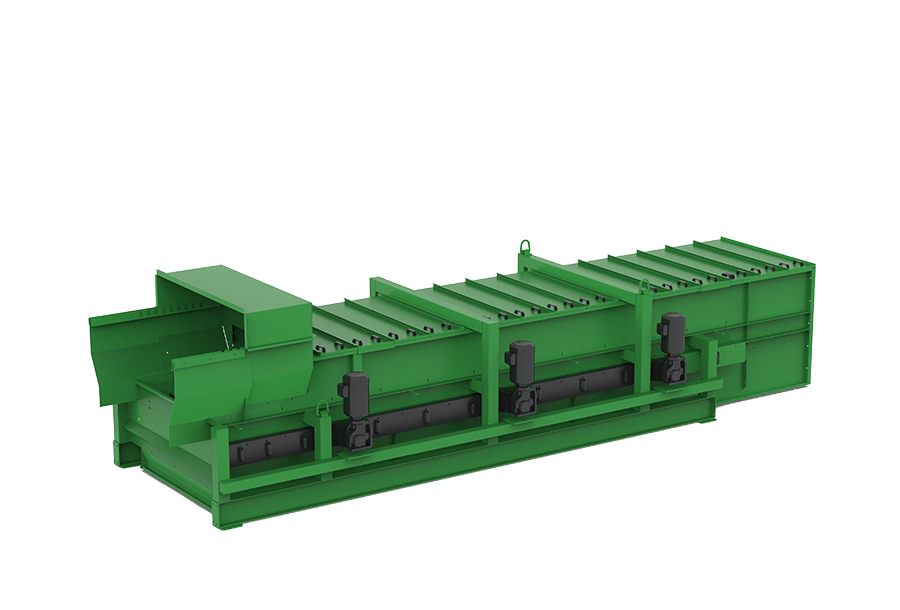

TAKER receiving unit

With the TAKER series, loose materials such as compost, wood, biomass, waste, metal, stones, etc. are accepted and made available for the next operation in optimum doses.

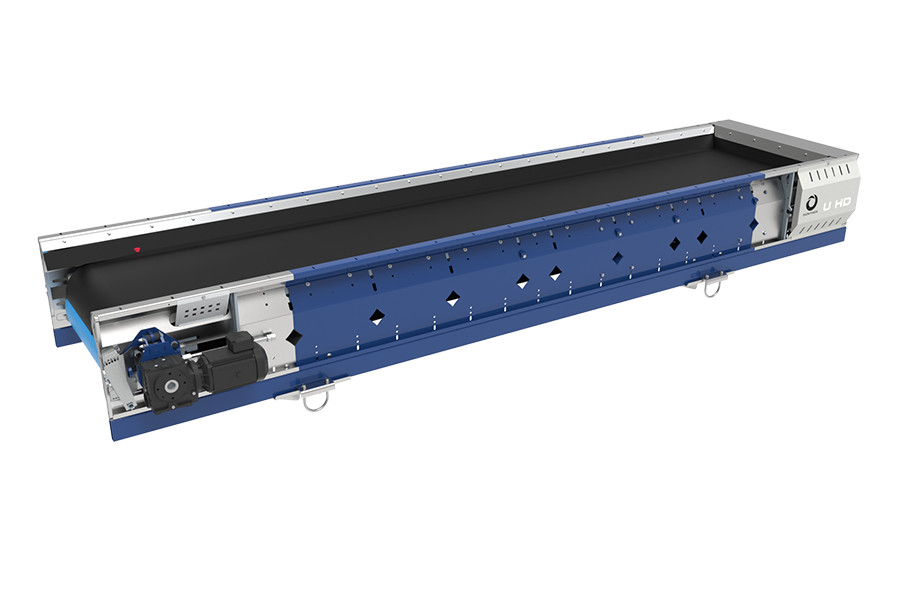

Conveyor technology

Our modular conveyor belt and belt conveyor systems offer you maximum flexibility and can be adapted smoothly and economically to your operating processes in a lot of applications.

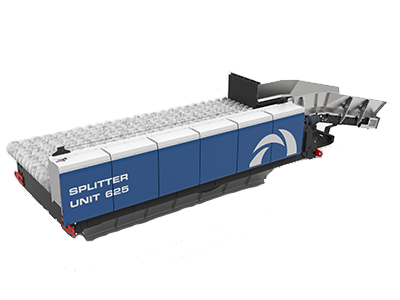

Spiral shaft screen

Domestic and commercial waste, waste wood, biowaste or mixed construction waste. The SPLITTER separation technology processes customer-specific materials at the highest level.

Star screen MULTISTAR

Star screen technology is increasingly being used in the elementary processing of waste, recyclable materials and biomass. And in many cases with a MULTISTAR.

Your contact persons