SPLITTER spiral shaft screen - the separation all-rounder

The powerful, self-cleaning and wear-resistant SPLITTER® spiral shaft separator effortlessly masters the most difficult tasks that push even proven separation technologies to their limits. Our patented screening system impresses with its high throughput and requires only minimal cleaning and maintenance. Separation itself is based on size, physical properties, weight and shape - up to three fractions are possible depending on the material composition.

The SPLITTER®, which appears to be driven and supported on one side (supported on both sides within the casing tube), combines the roller conveyor effect with the Archimedean screw principle. The material is transported laterally by the spiral shaft and simultaneously in the conveying direction by the roller track effect. This overlapping of movements distributes the material very efficiently and effectively. The special difference to conventional screening systems lies in the screen gap that runs out at the open end. This allows impurities to be discharged safely and gently. With this special design, the actual screen shafts constantly clean each other of build-up and windings.

The SPLITTER® is available in three different screen deck variants and therefore offers the right screening solution for almost any material.

Would you like an offer for a SPLITTER?

Customer benefits

Properties that make our SPLITTER to your advantage

- Patented system for separating the most difficult materials (e.g. unshredded screenings)

- Low-wear technology

- Clog and wrap-free screening

- Consistent screen quality

- High process reliability

- Especially against impurities such as FE, NE, glass and minerals

- Mobile and stationary design variants

- Can be used with various upstream and downstream machines for further processing

- Extremely powerful and cost-saving

- Space-saving integration into new or existing systems

- Metered discharge of the separated materials

- Low-noise operation

Advantages of using a SPLITTER before the shredder

- Up to 50 % lower operating costs due to

- SPLITTER as pre-separator (volume reduction)

- Reduction of wear costs on the shredder

- Reduction of energy costs

- SPLITTER as a good metering / levelling agent (even material flow)

How SPLITTER technology works

The function is demonstrated in an impressive way using various simulated materials. We would be happy to discuss the application with you in your specific environment and according to your needs! Visit our YouTube channel for further application and machine-specific examples and information.

Areas of application

Household and commercial waste

Household and commercial waste Biowaste and biomass

Biowaste and biomass Waste wood and bulky waste

Waste wood and bulky waste Construction waste and mixed construction waste

Construction waste and mixed construction waste

Landfill dismantling

Landfill dismantling Slag

Slag Metal waste

Metal waste Earthy excavation with stones

Earthy excavation with stones

Our stationary and mobile SPLITTERs

SPLITTER CUBE

The SPLITTER CUBE is ideal for sand treatment, e.g. road sweepings and sewer sand.

SPLITTER HOOK

The mobile SPLITTER HOOK achieves the highest possible screening performance on the smallest possible screening surface.

SPLITTER X2

The SPLITTER X2 is the expert for heavy, sticky and partially unshredded material.

SPLITTER H3

The mobile SPLITTER H3 is the expert for heavy, sticky material in the tightest of spaces.

MULTIWASH HOOK

The mobile MULTIWASH Hook combines the task of screening and washing in one unit.

SPLITTER F2

The SPLITTER F2 is the specialist for processing solid material with a wide range of adjustment options.

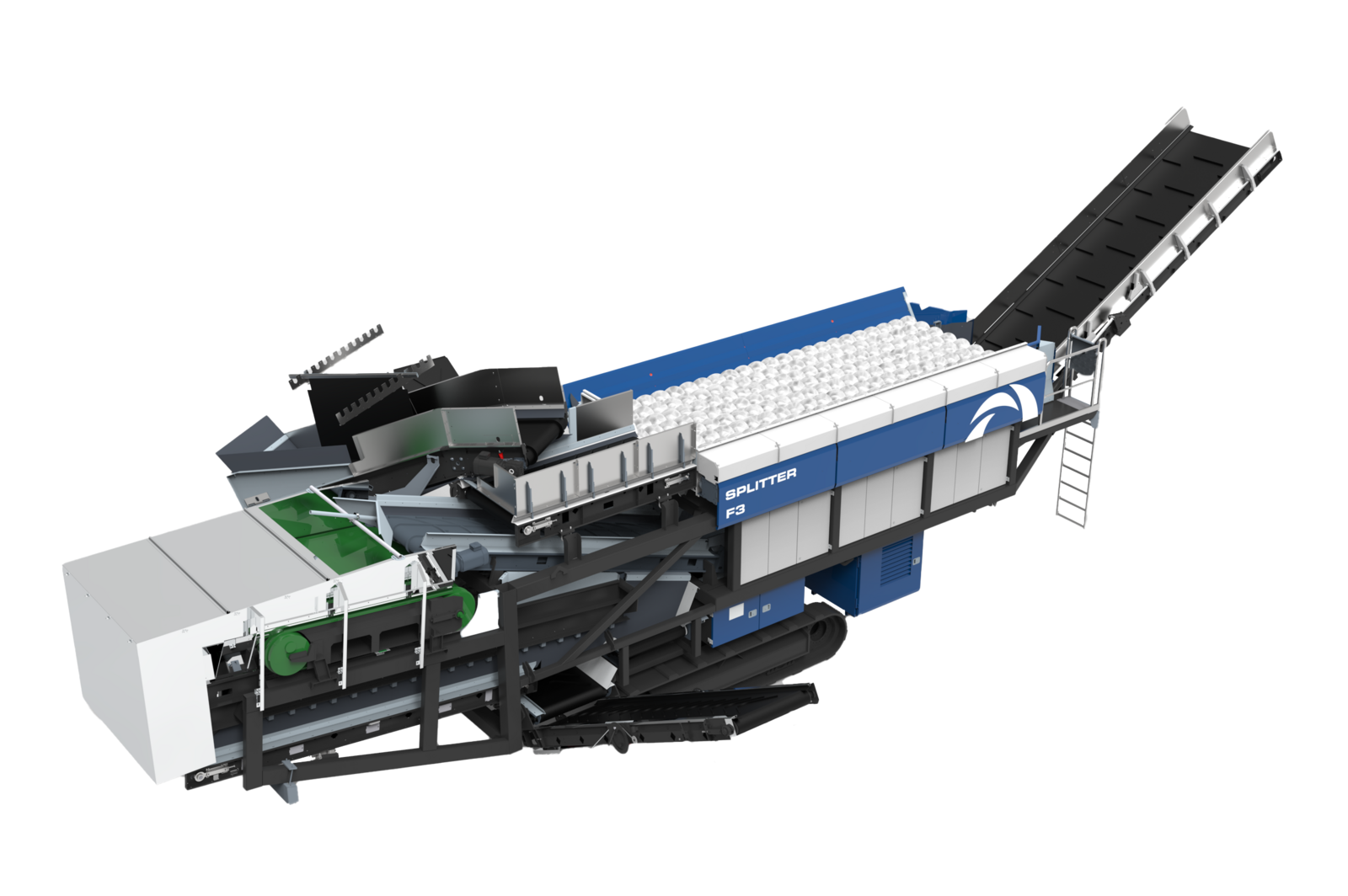

SPLITTER F3

The track-mounted SPLITTER F3 is the further development of the proven F2 in the F series.

Your contact person