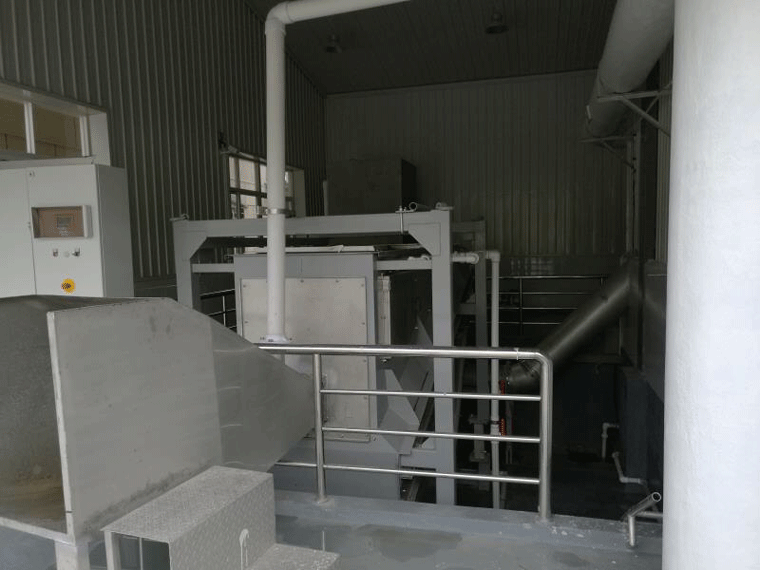

Star sieve MULTISTAR 2-SE Wet screen

The star screen technology from Komptech is one of the most efficient separation technologies in the field of primary sludge and faeces screening. The MULTISTAR star screens are characterized by their precise separation efficiency, regardless of the material consistency - solid, moist or liquid - and the ability to change the grain size produced at the touch of a button. The star screens are characterized in particular by their high throughput capacity in this area and their extremely low-wear operation.

Screening technology with patented Cleanstar® system

With the patented Cleanstar® system, the screens have an integrated cleaning system that works without contact and therefore protects against wear. The sieve stars are cleaned without additional brushes or washing water.

The MULTISTAR technology

is distributed exclusively by our partner

KOMPTECH.

Get information now

Highlights of the MULTISTAR 2-SE wet sieve

- High throughput capacity with exact separation precision even with moist materials

- Grain sizes can be changed in seconds thanks to simple speed adjustment on the screen deck

- Flexible modular solutions for special customer applications

- Industrial design for very high annual capacity utilization

Application examples MULTISTAR 2-SE wet screen

Advantages of the MULTISTAR 2-SE wet sieve at a glance

Drive

The inner workings of the star screens consist of high-quality components. The drive of the star shafts via electric motors with frequency converters ensures low energy, wear and maintenance costs.

Screen grain size

A complete range of grain sizes ensures the different designs of our individual star screens. By adjusting the rotational speed of the star shafts, the grain size can be changed within seconds within the bandwidth specified by the star geometry. Different star types and arrangements can be selected to cover screen sections from 6 - 20 mm or larger.

CLEANSTAR cleaning system

All screening elements are continuously cleaned by the cleaning system. Precisely matched cleaning elements are available for each area of application, enabling wear-resistant and therefore very economical operation.

Arrange a consultation right away:

Technical data

| Drive | Mains connection: 3 - 33 kW (depending on equipment plus options) |

| Screen section/screen deck | Coarse screen L x W (mm) / area (m²): 5863 x 1200 / 7.0 Fine screen L x W (mm) / area (m²): 5985 x 1200 / 7.2 Screen deck L x W (m): 2.5 x 1.0 Drive power: adapted Material grain size: 6....20 or larger |

| Areas of application | Primary sludge screening, faecal sludge, faeces, wet fermentation, paper sludge, food residues |

| Troughput | up to 250 m³/h (depending on material) |

| Options | Downstream screen drainage, complete cover for exhaust air connection, further options on request |

Your contact person