Conveyor technology, conveyor belt systems and conveyor belts for plant engineering

What is conveyor technology?

Conveyor technology is used in many industries. Whenever material has to be conveyed in any direction and over limited distances using technical aids, conveyor technology comes into play. In short: whenever material flow is involved, conveyor technology plays an important role.

Conveyor technology, in particular conveyor belts from GÜNTHER, have been developed based on the requirements for plant technology in the recycling sector. They are mostly used in sorting systems or in conjunction with separation technology, whether stationary or mobile.

Conveyor belts for plant technology

When planning a plant, the aim is to intelligently design the structure and logistics in the plant without requiring long transportation routes. However, even if the plant is well designed, the material still has to be transported from one unit to the next or into bunkers or stockpiles. For this reason, around 25% of a plant usually consists of conveyor technology.

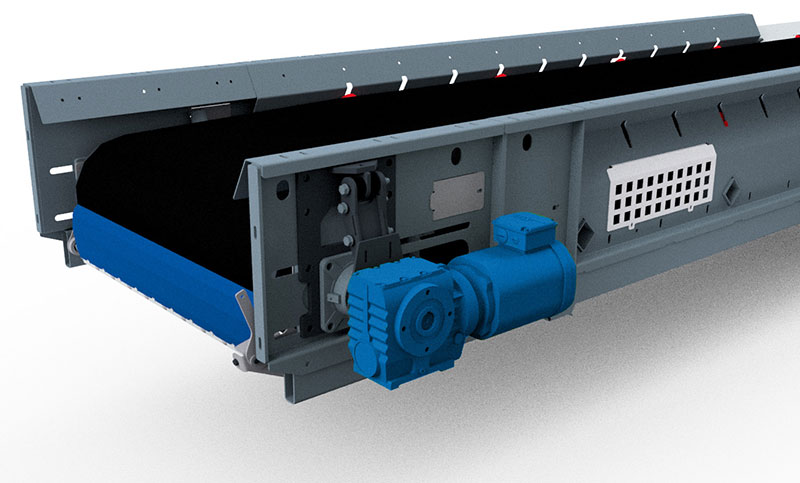

Functionality and structure of conveyor belts

Components of the conveyor belt:

- Conveyor belt

- Belt cheek/belt frame/steel construction/chassis/housing

- Speed monitor

- Ripcords

- Side guide rollers

- Inner belt scraper/plow scraper

- Drive and deflection drum

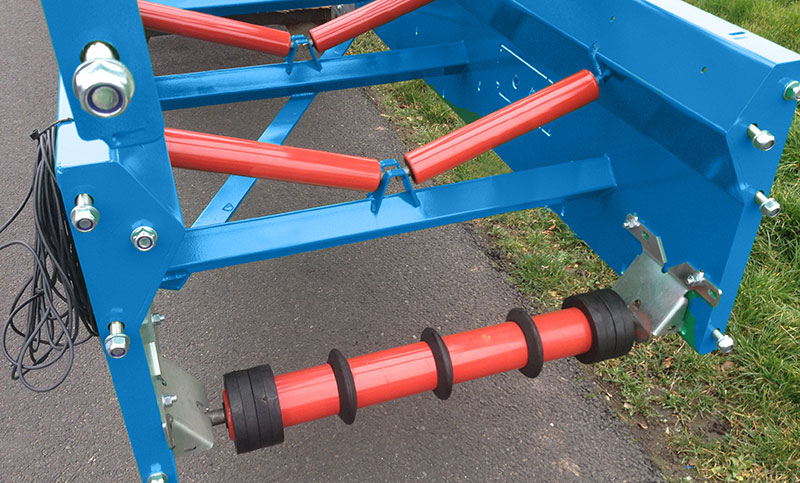

- Support station

- Support rollers

- Drive motor with bearings

- Bottom belt rollers/ return rollers

How the drive motor works

- The belt is driven on one side at the drive station with drive drum using a motor.

- The belt runs over the idlers or guide rollers. The deflection station with deflection drum is located on the other side.

- The last roller at the end of the belt is called the return roller. It is used to guide the belt back over the bottom belt rollers.

- The conveyor belt is usually driven in a pulling arrangement. A pushing drive is also possible if it makes structural sense and the belts are rather short.

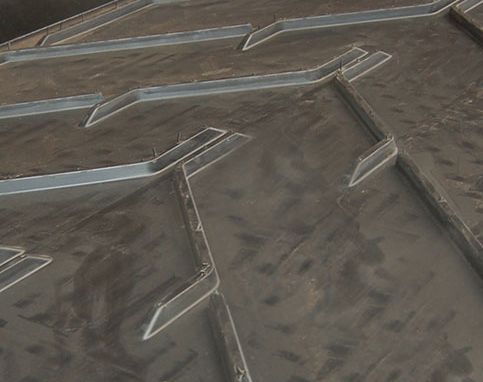

Functionality and profiles of the conveyor belts

Depending on the application or the material to be processed, the conveyor belt is fitted with a suitable profile from an incline of 20°. This prevents the material from rolling back down due to gravity. The profile is often designed in such a way that it not only catches the rolling material, but also guides it into the center of the belt to prevent the material from falling off the sides.

The profiles are usually hot vulcanized and cast directly into the mould. This is possible up to a profile height of 3-4 cm. If a higher profile is required, the T-cleat profile is usually used. In this case, the T-cleats are glued or screwed onto the belt.

Criteria and example for belt quality

- Tractive force

- Structure of the belt

- Resistance to chemicals and environmental influences

- The belt quality required depends on the material to be processed in a system.

- In this sense, quality says nothing about the quality of the manufacturer or the materials used, but about the tensile strength, the construction of the belt and its resistance to chemical environmental influences.

- If stones and soil are to be conveyed, a high tractive force is required. For organic waste, on the other hand, attention should be paid to oil and grease resistance rather than tractive force.

Do you have questions about conveyor belts from ANLAGENBAU GÜNTHER?

Belt conveyors - Conveyor belt systems

Conveyor belt as "flat belt" or "flat belt":

Flat belts are used in preparation for the process when feeding units such as star screens, SPLITTERs, vibrating screens, near-infrared systems, magnetic separators, air classifiers and other separation units. In order to process the material in screens, for example, it should arrive at the screen evenly distributed in a single grain layer on the belt.

Conveyor belt as "troughed belt" or "troughed belt":

Due to the design of the troughed belt, the material collects in the middle (trough) of the belt. This reduces the risk of material getting into the chassis, blocking rollers or slowing down the belt. A troughed belt is usually used for long transport routes so that the material is guided safely and does not fall out.

Conveyor belts from GÜNTHER

For simple or very demanding conveying capacities

GÜNTHER conveyor belts are made of high-quality components. The drive motors are adequately dimensioned and therefore offer sufficient reserves even with demanding materials. We install maintenance-free bearings that are standardized according to DIN and have proven themselves thousands of times over. This means less downtime due to maintenance work.

High-quality, sturdy and self-supporting sheet metal frame construction

The side walls of GÜNTHER conveyor belts are made from a continuous sheet metal edge section, which reduces the risk of injury and makes the conveyor belts less susceptible to external influences and soiling.

Features and advantages of GÜNTHER conveyor systems

- High standard of basic equipment

- Systems commonly used on the market are installed

- Compatible with common cover systems

- Standard idlers

- Bearings according to DIN

- hinged PU wipers

- Maintenance-free bearings

- low noise

- solid

- efficient

- economic

Do you have questions about conveyor belts from ANLAGENBAU GÜNTHER?

Products from GÜNTHER - solutions for your transportation needs

Modular uni-belt system

The universal

The modular design makes it possible to use thel Uni-Belt as a troughed belt for transport over longer distances or to install it as a flat belt in processing plants.

- Wide range of applications

- Lower transportation costs

- Available galvanized or painted

- Available bolted or welded

- Fast delivery times, shorter response times

- More flexible changes, extensions or conversions

Special belts for your individual system

Reversible belt - the flexible one

A reversible conveyor belt can change its direction of travel. This enables flexible applications within a system. The control of a reversible belt is adapted so that, for example, an overload of the downstream unit is automatically detected and the conveying direction is changed. The direction of travel can be changed manually at any time.

Reversible belt application examples:

If a box is full when discharging into the stockpile, the material is conveyed to the next box by changing the direction of travel.

Depending on the nature and feed situation within the system, it is possible to send the material via an additional or alternative unit.

Kink belt - the efficient one

When material is discharged via a horizontal belt and conveyed to the next unit via an ascending belt, a transfer situation arises between the belts that needs to be monitored regularly. By using an articulated belt, this - usually at the start of a process chain - is avoided and the process runs more smoothly.

Frequently asked questions about conveyor belts from ANLAGENBAU GÜNTHER:

We only use components from renowned manufacturers in our conveyor belts. Be it our bearing systems, the hot-vulcanized belts, idlers or our drive motors. We source our components from respected market leaders and attach great importance to quality goods and adequate dimensioning of the drive power of the motors used.

GÜNTHER offers a high level of basic equipment. We deliver uncompromising safety and quality. The all-round carefree package is not optional with us, but is part of the basic equipment.

Each of our conveyor belts is equipped with, among other things, an intervention guard, speed monitor, rip cords, side guide rollers and inner belt scraper/plow scraper.

Yes, they are maintenance-free. We use DIN-standardized, maintenance-free 4-hole flange bearings and PHUSE bearings. These do not require regular lubrication and downtime due to maintenance is a thing of the past. This is particularly advantageous for conveyor belts, as they are often installed in a system that is difficult to access.

This technology has proven itself thousands of times over the years in which we have been using it.

Your contact person