What does plant engineering mean?

In plant construction, technical components are brought together to form an overall process. The construction of a plant is therefore not a series or mass product, but is adapted to the conditions and wishes of the customer as well as the objective. Plant engineering includes process engineering, mechanical engineering and electrical engineering. Plant engineering can be found in a wide variety of economic sectors.

What systems does ANLAGENBAU GÜNTHER build?

GÜNTHER's plant engineering is specially adapted to the requirements of the recycling industry. Our core competence lies in the area of processing and sorting plants for various waste and recyclable materials. For decades, we have been developing intelligent technologies in the field of mechanical treatment and holistic concepts for waste management.

Which common materials can be processed with a recycling system from ANLAGENBAU GÜNTHER?

Do you have questions about our processing and sorting systems?

What advantages do you have with a recycling system from ANLAGENBAU GÜNTHER?

- Use of high-quality components from our own company

- Partner and manufacturer-independent use of industry-standard units

- Turnkey solutions for many materials

- Intensive advice from experts and industry insiders

- Made in Germany

- High vertical range of manufacture at GÜNTHER internally

- Reduced interface clarification

- A permanent project manager as contact person for all concerns

- Technically trained specialists

- The GÜNTHER assembly teams are largely made up of GÜNTHER's own employees, who monitor the process and tackle the work themselves.

- The complete electrical engineering comes from our company as an option

- High flexibility and adaptability to customer requirements

- High quality standards

- Renowned manufacturers for purchased parts

- Reuse of existing units possible

- Comprehensive after-sales service

From the initial idea to production and assembly from a single source worldwide

With our own extensive product range in intake and screening technology, it is not uncommon for us to supply individual units as the main components for state-of-the-art processing and sorting systems. In addition to the individual components, we are also able to supply turnkey systems including electronics.

In addition, we face many challenges. We have already been able to realize many plants in the field of recycling technology with many different conditions and materials. For example, we plan and implement sorting plants for waste wood or lightweight packaging (LVP) or construct treatment plants for processing domestic and commercial waste and the production of refuse-derived fuel (RDF). Another of our strengths in the area of processing plants is in the field of biowaste, green waste and compost.

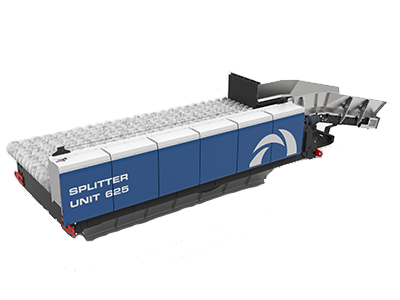

Our unique SPLITTER technology can be used to screen a wide variety of materials - a real all-rounder. This is why this technology is often a desired main component in our systems for economical recycling.

How do waste sorting systems work?

MULTISORT - Sorting plant for processing commercial waste into RDF

The plant was built in 2020. Every hour, 25-30 tons of commercial waste are processed into substitute fuel. The plant uses a SPLITTER Unit 625, a double-deck screening plant, air classifier, light material separator with bag filter, conveyor technology as well as FE and NF separation.

A well thought-out design enables different operating modes and therefore several output qualities. The control technology from GÜNTHER included in the scope of delivery also incorporates the pre- and post-shredder.

MULTISORT - Sorting plant for processing waste wood

The plant was built in 2020. It processes 30-33 tons of waste wood per hour. The plant uses a pre- and post-shredder, FE and NF separation, an air separator, conveyor technology and a MULTISTAR 2-SE star screen.

The system was also supplied by GÜNTHER including the control technology, into which the shredding technology was integrated. This is located in a specially designed electrical container.

Sorting plant for lightweight packaging

A wide variety of separation technologies are used in the system: SPLITTER, vibrating screens, FE and non-ferrous separators, NIR sorting technology, heavy material separators and several film extraction systems. The material is fed into the process on a chain belt conveyor as a feeding unit. A shredder serves as a bag ripper and distributes the loose material to two material flow lines.

A double SPLITTER screen deck is used to process the two material flows and thus ensure a high throughput. It reliably removes long parts and oversized materials such as film and bags from the material flow. The fine fraction first passes through a vibratory screen, a counter-rotating non-ferrous and ferrous de-airing system, an air classifier and several near-infrared systems (NIR separators), which sort the various plastics into PET, Tetra, PPK, PP, PVC and HDPE/PE based on their physical properties.

Do you have questions about our processing and sorting systems?

ANLAGENBAU GÜNTHER - plant engineering "Made in Germany"

At our Wartenberg site in Germany, we have in-house specialists in all departments, from process technology, engineering and electrical engineering to our mechatronics engineers, who provide comprehensive after-sales support. Our employees include experts who have been with us or in the industry for many years, as well as young employees who have the necessary vision. Our high training and hiring rate also enables us to secure our specialists for the long term. We therefore cover the entire value chain in-house. From sales and conceptual design to construction, manufacture, assembly, training, commissioning, service and spare parts supply. Every day, over 135 employees at ANLAGENBAU GÜNTHER work closely with customers to develop cost-effective solutions for recycling systems.

The project team at a glance:

Project planners,

who are very familiar with the industry and provide you with competent support from the initial idea to the finished concept.Project engineers and designers,

who visualize the finished concepts and prepare them for production. In this way, we ensure that all the technical background is correct and that the error rate in production and assembly is subsequently minimized. We provide you with the 3D drawings during the planning stage so that you get the best possible idea of your system in advance.Employees in production and final assembly,

The individual parts and components are manufactured in our spacious assembly hall and then approved by quality assurance.Employees in the electrical department,

who implement entire control systems for the plants. Here, plans are drawn up first, followed by control cabinets and cabling for the individual units.Project manager,

who are always your point of contact during the implementation of the project. They will clarify all questions relating to the project for you. This means that you only have one contact person who you can fall back on and rely on at all times. Our project managers each have technical training and experience as well as the necessary foresight.Employees in the areas of service, spare parts supply and worldwide support.

They carry out installations, handle commissioning, train our customers in handling the system, carry out regular maintenance and UVV inspections and support you in all other future concerns with your

system - in German and English.

Our customers benefit from:

High vertical range of manufacture:

As we work and manufacture so extensively in-house, many interfaces can only be clarified internally. You do not have to spend a lot of time and effort planning and installing the system yourself. You clarify all questions with our project manager, your contact person.Individual customization:

If changes are made to the project, we can usually implement them without complications. Problems can usually be solved with less effort.Fast response time:

As soon as you contact your project manager, he or she will take care of clarifying all your concerns as quickly as possible. This also means that we can react very sensitively and flexibly.Flexibility is our strength:

Both in planning and in implementation. We are able to adapt our ideas to your circumstances. This starts with the question of local conditions. Whether an existing building, a planned conversion or a new build - we design our systems intelligently, as space-saving as possible, but accessible. We adapt them precisely to your ideas and circumstances.

Our services

Our highly qualified service team ensures the continuous, smooth and efficient use of your system even after completion.

For fast availability of spare parts and expert advice, please contact us on our service hotline.

Process flow at Anlagenbau GÜNTHER

Our process engineers develop a plan for the system based on the objectives and decide which components are to be used in which order in the system. In the next step, the system is coordinated with the design engineers. They design the system and create 3D views. If necessary, everything is checked statically and the electrical engineering is coordinated. Drawings are then created for production. The individual system components are manufactured in our production hall. Our production includes steel construction, painting, final assembly and electrical assembly. Everything has to work hand in hand here. If there are any questions or uncertainties, we have short lines of communication between project planning, design and production.

The machines are then approved by quality management at the factory and finally dispatched. When they arrive at the customer's premises, our assembly team is ready and waiting. This consists largely of mechatronics engineers who are highly skilled in both mechanical and electrical engineering. Once the system has been completed, approved and commissioned at the customer's premises, our service team is available to the customer as a point of contact. They carry out training, regular inspections and maintenance, dispatch and install spare parts and advise our customers on further decisions.

Recycling technology with quality

We ourselves manufacture star screens (in cooperation with Komptech), SPLITTER, intake feeders and conveyor technology, among other things. Of course, we are happy to use these core competencies at the appropriate points in the system - because we are convinced of the quality and functionality of our technology.

In addition to our own portfolio, we also use other components regardless of the manufacturer. The units can be planned and integrated according to customer requirements.

We also take great care to ensure that purchased parts come from reputable manufacturers. We purchase a wide range of separation technologies for our plant construction from various renowned suppliers. These include Shredders, magnets, non-ferrous separators, air classifiers, sensor technology and various screens. We provide competent, manufacturer-independent and customer-oriented advice on the use of various units.

Thanks to their technical expertise, our process engineers and designers are also able to incorporate existing units into the planning and install them in a new system. Recycling" is therefore possible.

For the implementation of successful projects, it is not relevant whether you come to us with a problem, an initial idea or a finished concept. You tell us the goal you want to achieve with the system, such as meeting the recycling quota, increasing throughput or achieving a high sorting depth, and we create ready-made, functioning and efficient concepts.

Our components:

- Star screens

- SPLITTER

- Acceptance feeder

- Conveyor technology

- Electrical engineering

- Steel construction and inspections

Other components:

- Shredder

- FE separator

- NE separator

- Wind sifter

- NIR separator

- Various sieve systems

- Sorting cabins

- Extraction systems

Receiving feeder TAKER

With the TAKER series, loose materials such as compost, wood, biomass, waste, metal, stones etc. are accepted and made available for the next operation in optimum doses.

Conveyor technology

Our modular conveyor belt and belt conveyor systems provide you with maximum flexibility and adapt smoothly and economically to your operating processes.

Spiral screen SPLITTER

Domestic and commercial waste, waste wood, biowaste or mixed construction waste. The SPLITTER separation technology processes customer-specific materials at the highest level.

Star screen MULTISTAR

Star screen technology is increasingly being used in the elementary processing of waste, recyclable materials and biomass. And in many cases with a MULTISTAR.

Corporate philosophy

We at Anlagenbau GÜNTHER are a medium-sized, family-run company with a long tradition. We have always focused on providing our customers with individual and comprehensive advice in order to complete functioning projects to their satisfaction. Our company is so large that we can employ many specialists and cover the entire supply chain. But we are small enough that we don't have rigid structures that make communication difficult. This allows us to react individually, flexibly and quickly to customer requests.

- "You tell us your goal, we plan and align your system accordingly".

- "You have a request, your project manager will take care of everything".

- "Our quality standards are high, which is why we only purchase parts from renowned manufacturers"

- "With us you get turnkey solutions and your effort to clarify interfaces is minimized".

- "The system is ready when the customer is satisfied"

Your contact person