MULTIWASH HOOK - Removing organics from the channel sand

Disposing of the materials that arise during the maintenance of our sewer system is often a major challenge. GÜNTHER supplies stationary and mobile processing technology to process these materials, such as road sweepings, cesspit material, faecal sludge and sewer sand, as efficiently and recyclably as possible.

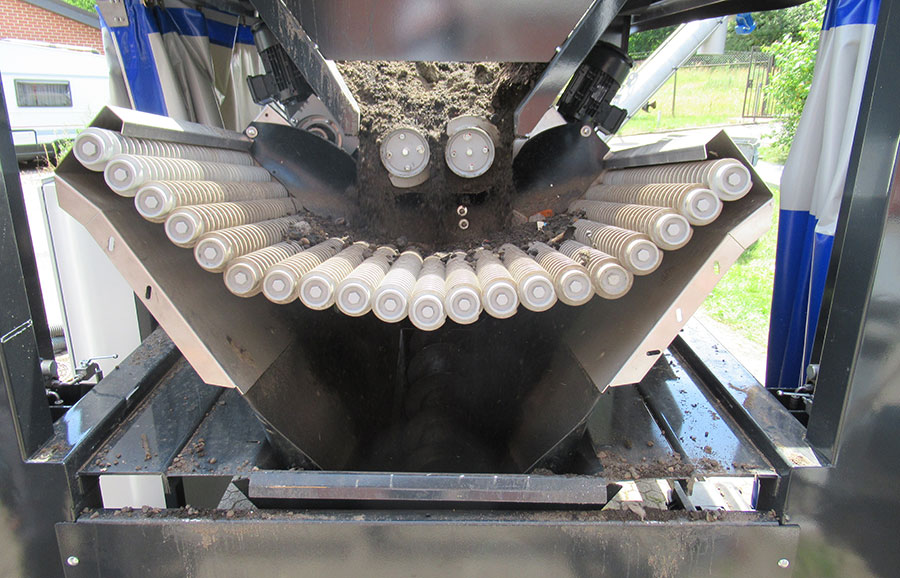

Both dry and wet materials can be screened using the SPLITTER spiral shaft screen. This allows contaminants such as stones and hygiene articles to be separated before the material is washed, freed of organic material and prepared for the efficient recycling process.

Application

What is processed?

- Road sweepings

- Fecal sludge

- Sewer grit (caisson material, contents from the vacuum truck)

What is the goal:

Remove organic material from the sand (max. 3-5%) so that the sand can be fed into the recycling process at low cost.

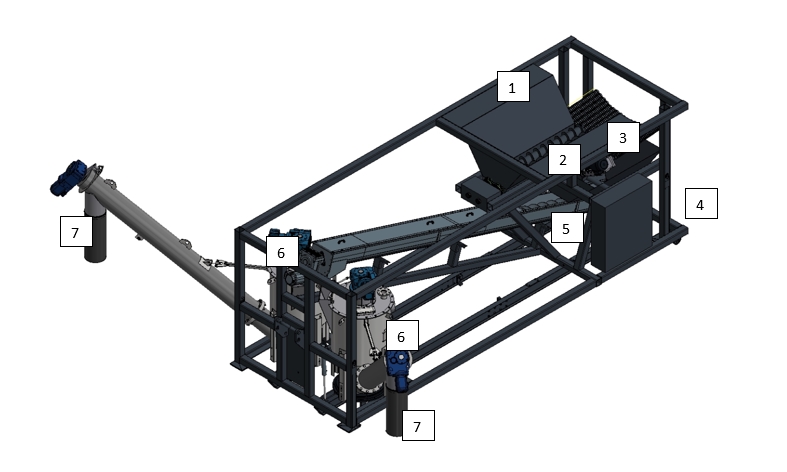

How the MULTIWASH HOOK works

The material - liquid or dry - is fed via the feed hopper (1). From this, the material is metered onto the SPLITTER screen deck via an auger at the bottom of the hopper (2). The conveying capacity from the hopper to the screen deck often depends on the nature of the material and can be adjusted via a frequency converter. In the screen deck - SPLITTER Twin Wave - impurities are screened off (3). The screen cut is 15 mm. This removes impurities that interfere with the rest of the process. The SPLITTER Twin Wave is designed so that the material remains on the screen deck for a long time (more activity in the material), which has a positive effect on the screening process. For example, sand that is entangled in a film can be loosened and is not discharged too quickly in the oversize grain. The angle of the screen deck can be adjusted so that the residence time of the material on the screen deck can be influenced. In addition, the oversize grain is pre-washed; this can optionally be done by installing nozzle bars.

The oversized particles - for example stones, leaves, paper, glass, hygiene articles - are discharged directly in the oversized particles (4). The undersize particles (organics, sand and water) are collected in the collection hopper under the SPLITTER and transported to the grit washers in doses using a grit conveyor screw with a center shaft (5). The filling level of the hopper is monitored using an ultrasonic probe. An overflow is integrated in the hopper, allowing excess water to run off. The sand is washed in the sand washer and organic matter is removed (6). The washed sand is discharged on two sides (7).

You want to test your material:

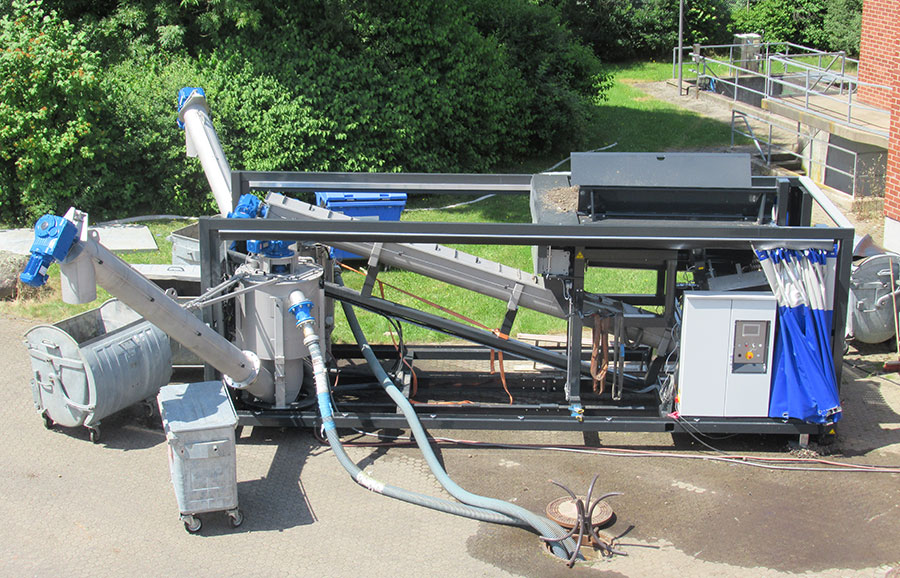

Advantages of mobility

A building permit is required for stationary systems, which must be installed in a hall at a fixed location. This results in additional acquisition costs and work around the machine. The mobile version does not require planning permission and can be moved and transported as required. It is equipped with a hook lift frame. For transportation, the pipes for material discharge are rotated and the machine is covered with a tarpaulin. This compact design makes it easy to transport by truck. This sophisticated design also allows the machine to be used directly on site for sewer cleaning. The pumped sewage sludge can be passed directly through the system and does not have to be transported away in several trucks for washing or disposal. This not only saves CO2, but also promotes the recycling process and has a positive effect on disposal and corresponding costs. As the organic material, which also binds water, is separated out during the process, the material to be disposed of becomes lighter and smaller in volume.

Rotatable mounting of the sand washer so that it can be swiveled into the frame for transport.

Learn more about the topic:

Advantages of the MULTIWASH HOOK system

- Unique, self-cleaning screening system

- External dimensions of the machine = internal container dimensions = low transportation costs

- Simple assembly and handling

- Very stable design

- Completely pre-assembled and ready for operation

- Simple adaptation to existing stock

- Various project-related options possible

- Two in one: Can be used as a reception station for sand and faeces

Technical data

| Drive | Mains connection (CEE plug 400 V/32 A), drive power 23 kw 400 V/50 Hz |

| Material feed | Dosing hopper Task height: minimum 2.6 m (floor-standing) Conveying unit: 2 SPLITTER shafts |

| Screening section | L × W: 1,5 × 1,0 m/Surface: 1,5 m2 |

| Screening deck | 0...15 mm und 0...11 mm |

| Screening deck | SPLITTER: TWIN WAVE |

| Material discharge | Discharge height 2,5 m for sand discharge |

| Discharge belts | Material is discharged via screw conveyors |

| Troughput | up to 6 t/h (depending on material) |

| Weight | 8 t (not including options) |

| Dimensions | L × W × H: 7,4 × 2,55 × 2,6 m |

| Operating | Touch panel and wireless remote control (optional) |

| Areas of application | Road sweepings, faecal sludge, sewer sand and similar materials with a high water content |

| Special feature | for 2 sand washingmachines 2 l/s at 2 bar (Water usage per unit 1 l/s) |

Our mobile machines

MULTIWASH HOOK

The mobile MULTIWASH Hook combines the task of screening and washing in one unit.

SPLITTER CUBE

The SPLITTER CUBE is ideal for sand treatment, e.g. road sweepings and sewer sand.

Your contact person