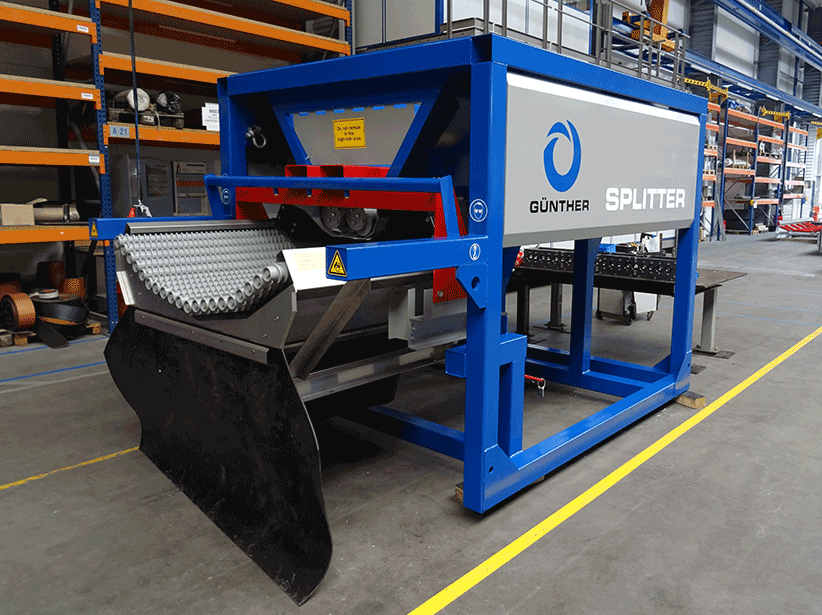

Spiral shaft strainer SPLITTER CUBE

The SPLITTER CUBE has been specially developed for screening in the area of channel sand intake. The machine can be supplied either in the Flat version as a three-fraction screen or in the Twin Wave version as a two-fraction screen. Different screen cuts are possible for both machines: 0...15 mm or 0...22/37 mm. The material is fed via a vibro or flume chute.

The space-saving version for versatile applications

When used for sewer sands or faeces, the feed can take place including water; prior separation of the liquid is not necessary. The splitter works without additional cleaning elements such as brushes. With the Twin Wave version, the material remains on the screen deck for longer. This makes it easier to loosen clumped material and additional washing is possible. Both versions impress with their compact design. Thanks to the compact size of the SPLITTER CUBE Twin Wave, it can even be used in mobile systems.

Advantages and customer benefits of the SPLITTER CUBE

- Flexible material intake dry or wet

- Self-cleaning system, no brushes or water required

- High throughput of up to 15 m³/h solids

- No plait formation with winding materials

- Lowest cleaning and maintenance requirements

- Low space requirement and low construction costs

- Can be optimally combined with various upstream and downstream machines and their further processing

Learn more about the topic:

Technical data

| Flat Screen deck | Twin Wave Screen deck | |

| Screen deck | Length: either 3 m or 2 m Width: 1.2 m or 1.5 m Drive power: 2x4 kW or 1x4 kW Material grain size: 0..22/37 mm or 0..15 mm | Length: 1 m Width: 1.5 m Drive power: 2x4 kW or 1x4 kW Material grain size: 0..22/37 mm or 0..15 mm |

| Dimensions | Transport: (LxWxH) 5.8 x 2.22 x 2.21 m | Transport: (LxWxH) 3.5 x 2.2 x 2.2 m |

| Applications | Road sweepings, sewer sand collection, fecal sludge, fecal matter, scrap metal | Road sweepings, sewer grit reception, caisson material |

| Options | Vibratory chute, flume chute, advanced conveyor technology, sand washing system - Further options on request - | Vibratory chute, flume chute, advanced conveyor technology, sand washing system - Further options on request - |

Our mobile machines

MULTIWASH HOOK

The mobile MULTIWASH Hook combines the task of screening and washing in one unit.

SPLITTER CUBE

The SPLITTER CUBE is ideal for sand treatment, e.g. road sweepings and sewer sand.

Your contact person