Separate

One of the mechanical separation techniques is sieving. By passing material through a sieve with defined openings, particles are separated according to size. At ANLAGENBAU GÜNTHER, we manufacture machines with different screening and separation technologies: spiral shaft screening technology, star screening technology, metal separation technology and steel disk screening technology.

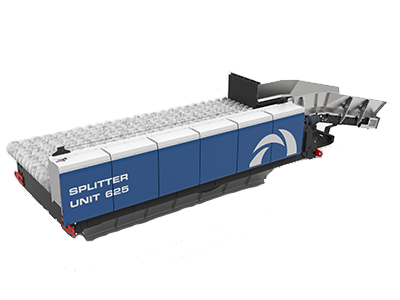

SPLITTER spiral shaft screen - the separation all-rounder

The powerful, self-cleaning and wear-resistant SPLITTER® spiral shaft separator effortlessly masters the most difficult tasks that push even proven separation technologies to their limits. Our patented screening system impresses with its high throughput and requires only minimal cleaning and maintenance. Separation itself is based on size, physical properties, weight and shape - up to three fractions are possible depending on the material composition. The SPLITTER®, which appears to be driven and supported on one side, combines the roller conveyor effect with the Archimedean screw principle. The material is transported laterally by the spiral shaft and simultaneously in the conveying direction by the roller conveyor effect. This superimposed movement distributes the material very efficiently and effectively. The special difference to conventional screening systems lies in the screen gap that runs out at the open end.

Our MULTISTAR starscreens - The starscreen technology of our starscreen machines stands for economy and efficiency

Screening is an elementary treatment step in the processing of waste, recyclable materials and biomass. Star screen technology is increasingly being used for this purpose. And in most cases it is a MULTISTAR star screen. It's easy to explain why: one machine and one operation are enough to divide the screened material into 2 or 3 fractions in exact screening. The throughput rate and separation efficiency are maintained even with increasing material moisture - thanks to the patented CLEANSTAR cleaning system.

If you want to adjust the grain size, all you have to do is press a button - the machine does the rest. Thanks to the highly efficient drive, screening is quiet, safe and economical. You will find the right equipment for almost every application and plant size. The screening plant becomes multifunctional through extensions such as magnetic separation, air separation or roller separation - everything is possible.

Non-ferrous and ferrous metal separator

The hook-lift mobile non-ferrous and ferrous metal separator Metalfex Hook can separate non-ferrous and ferrous fractions from various materials. The material is fed with an external customer-supplied feed conveyor, directly through an upstream shredder or other system technology. The speed of the integrated intake and feed belt can be individually adjusted for optimum separation of the non-ferrous material. An optional material distribution plough can distribute any narrowly tracked material flows to the required belt width. The high-quality eddy current separator is also equipped with an adjustable eccentric pole system and is therefore easy to adjust to the respective material requirements. Two one-piece buckling discharge belts ensure the safe discharge of the removed good material on the one hand and the extracted non-ferrous metals on the other. All functions are controlled via an intuitive control panel on the machine.

Disk separator and steel disk screen FLOWERDISC

The FLOWERDISC is another technology for screening pre-shredded commercial and bulky waste as well as biowaste that effectively combines high throughput, separation efficiency and resistance to contaminants.

How the steel disk screen works

The steel disk screen principle uses shafts with robust steel disks to transport the material. Jamming and blockages caused by impurities are prevented by movable, elastically mounted casing tube bodies between the discs.